Corn Mill Grinder | Disk Mill Machine

| Brand | Taizy Machinery |

| Power | 1.8kw |

| Capacity | 50-150kg/h |

| Weight | 40kg |

| Size | 300*400*530mm |

You can now ask our project managers for technical details

The corn mill grinder, also known as a flour and pulp grinder or disc mill machine, is a multifunctional and efficient grain processing device mainly used for grinding corn, wheat, rice, sorghum, and other cereal crops into fine powder.

The small household-use corn mill grinder offered by Taizy has an output of 50–150 kg/h and is widely used in food processing, animal feed production, household workshops, and small-scale grain and oil mills.

This machine is equipped with high-quality cast iron grinding plates, making it durable and easy to clean. The entire structure is made of premium carbon steel or stainless steel, ensuring corrosion resistance and a service life of over 10 years.

Thanks to its compact size, simple operation, and affordable price, our disc mill grinder is highly popular among customers and has been exported to countries such as the Philippines, France, and Tonga.

What are the advantages of a corn mill grinder?

Small footprint & compact structure – Ideal for household workshops, small factories, or processing environments with limited space.

Wide application range – Suitable not only for grinding corn but also for wheat, sorghum, soybeans, fish bones, dried chili peppers, and various other grains and dry materials.

Multiple models for flexible choice – We offer a variety of electric disc mill models to meet different production capacities and user needs.

Easy operation & labor-saving – Simply pour the material into the feeding port, and the machine will automatically complete the grinding process.

Adjustable grinding fineness – Users can freely adjust the powder fineness (from 0.2mm to 8mm) based on different applications, from coarse to fine powder.

Equipped with a dust removal system for cleanliness – Built-in cyclone separator effectively collects dust, improves air quality in the workshop, and protects the health of operators.

Various power options available – Depending on actual working conditions, users can choose between electric motor, diesel engine, or gasoline engine to suit different environments.

Durable material – This heavy-duty grinder features a robust iron body, ensuring long-term use and reliable performance.

Application scope of the disk mill machine

Processable Materials

- Dried corn kernels

- Soaked corn

- Rice and paddy

- Sorghum and wheat

- Sesame and peanuts

- Various types of beans (such as soybeans, mung beans, etc.)

Application scope

Due to its advantages of small size and easy operation. This industrial corn grinder can be used in rural areas, small grain processing plants, feed processing plants, grain and oil markets, supermarkets, schools, and restaurants. You can use it to process various grains.

Working principle of corn mill grinder

This corn mill grinder utilizes an efficient physical grinding structure, combined with multiple power options and an advanced dust removal system, to achieve high-efficiency and controllable grinding of grain materials. Its working principle is as follows:

Multiple power drives

The machine can be equipped with different types of power systems based on user needs:

- Electric motor: Suitable for areas with a stable electricity supply; operates with low noise.

- Diesel engine: Ideal for areas without electricity or an unstable power supply.

- Gasoline engine: Highly portable, suitable for outdoor or temporary operations.

Dual feeding ports

The equipment usually has two feeding ports. Users can select the appropriate feed path according to the material characteristics and processing requirements, enabling continuous and efficient feeding to increase productivity.

Rotary grinding system

After entering through the feeding port, the material falls into the internal rotary disc grinding chamber. Driven by the motor, the grinding disc spins at high speed, generating strong shear and friction forces to quickly crush and grind the material.

Flat tooth grinding structure

The grinding disc is equipped with alternating long flat teeth and short flat teeth:

- Long, flat teeth perform the primary coarse crushing.

- Short, flat teeth further grind the material into finer particles.

Together, they can grind the material down to starch-level fineness.

Adjustable grinding fineness

By adjusting the gap between grinding discs, users can precisely control the particle size of the output powder, with a range from 0.2 mm to 8 mm, meeting various needs from coarse to fine powder.

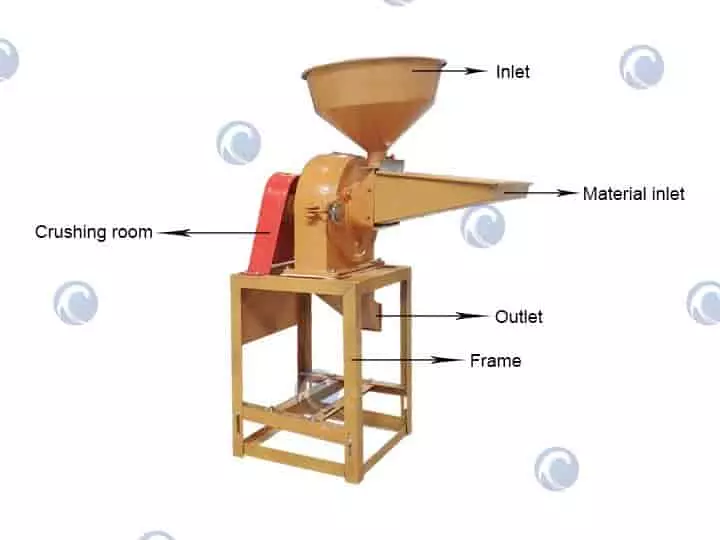

Structure of the corn grinding machine

Dimensions of the corn mill grinder

Parameters of the disk mill machine

| Model | SL-80 | SL-150 |

| Power | 1.1KW | 1.8kw |

| Capacity | 50-80kg/h | 150kg/h |

| Weight | 34kg | 40kg |

| Size | 300*300*465mm | 300*400*530mm |

Our machines support customized power supply and voltage configurations to suit the standards of all countries worldwide. Feel free to contact us for more information!

How to use the corn milling machine

Raw material preparation

Clean the corn thoroughly and peel off the outer skin using a knife. This helps improve flour yield and the quality of the final product.

Feeding the machine

Place the cleaned and peeled corn into the machine’s feed hopper, ready for grinding.

Power connection

Plug in the machine and turn on the power switch. Ensure the machine starts running smoothly.

Adjusting flour fineness

Adjust the outlet gap or change the screen mesh according to your needs. For fine corn flour, use a fine mesh sieve to ensure the desired powder texture.

Start milling

Feed the corn evenly and at a steady pace. Avoid overloading the machine to ensure consistent and fine output while protecting the motor.

Maintenance guide for corn milling grinder

- Unplug Before Cleaning: Always disconnect the power before cleaning the machine to prevent electric shock or accidents.

- Cleaning and Care: Use clean water to wash the exterior and interior parts of the machine. Wipe dry with a cloth to prevent rust and maintain hygiene.

- Lubrication: Regularly apply lubricant to the designated parts to ensure smooth mechanical operation and extend the machine’s lifespan.

- Storage for Long-Term Inactivity: If the machine will not be used for an extended period, protect it from moisture and dust by storing it in a dry, well-ventilated area.

Corn mill grinder purchasing guide

When selecting a small corn flour mill, it is recommended to consider the following factors:

- Production capacity: Choose a suitable power and model based on your daily processing volume.

- Power supply conditions: Determine whether you have stable electricity; consider electric motors or diesel engines accordingly.

- Grinding fineness requirements: Some users need coarse flour, while others require fine powder—make sure the sieve configuration matches your needs.

- Multi-functionality: Consider whether you also want to process other materials, such as chili, beans, etc.

- Spare parts and after-sales service: Give priority to manufacturers who provide spare parts support and technical guidance.

What are the types of corn mill machines?

In the Taizy corn machinery factory, we have an SL-150 corn hammer mill, a multi-functional grain grinder, a grain crusher with a cyclone separator, and other corn mills.

Compared with the disk mill machine, the powerful engine of the SL-150 corn hammer mill only needs to drive the hammer head to swing, instead of the entire grinding plate. So it is more energy-saving than the disk mill. A multifunctional grain grinder is also called a corn grits making machine. It can make corn into large grits, small grits, and corn flour. Therefore, this multifunctional grain grinder is more practical.

Cyclone grain crushers can also handle a variety of materials. The difference is that there is a jar in the device. This grain grinder has a dust removal tank. It can collect dust when the machine is working.

You can choose your own industrial corn grinder according to your needs. If you have any questions, please feel free to contact us.

Why do customers choose us?

- We are not only a corn flour machine manufacturer but also a professional corn processing equipment manufacturer. Therefore, compared with other manufacturers, we are more professional.

- Better after-sales service. We not only have good pre-sales service but also the same after-sales service. When customers encounter problems, we will help them solve them the first time. Therefore, many customers have become our repeat customers.

- Fast delivery speed. As is common in corn processing equipment, the corn mill grinder has a lot of stock in our factory. Therefore, our delivery speed is very fast.