4-6 Tons/h Large Scale Corn Threshing Machine

| Model | 5TY-80 Series |

| Capacity(t/h) | 4-6 (corn seeds) |

| Power | 15HP diesel engine or 7.5 KW motor |

| Breakage rate | ≤1.5% |

| Threshing rate | ≥99.5% |

| Loss rate | ≤2.0% |

| Impurity rate | ≤1.0% |

| Size(mm) | 2360*1360*1480 |

You can now ask our project managers for technical details

The large corn threshing machine is a highly efficient agricultural machine designed for quickly threshing harvested corn and separating the kernels from the cobs.

According to different configurations and processing capacities, Taizy offers four models: 5TY-80A, 5TY-80B, 5TY-80C, and 5TY-80D. The high-output corn thresher machine has a production capacity of 4-6 tons per hour. And it has the characteristics of low dust and low damage rate.

This corn thresher uses a single conveyor for feeding, achieving a one-time threshing rate of 99.5%. It can also completely separate the corn kernels from the cobs. Equipped with a 15 HP pure copper motor, it delivers strong power, supports long-term threshing operations, and prevents motor burnout.

The large-scale corn threshing machine is a hot-selling thresher from Taizy Corn Machinery Factory. So far, the machines have been exported to Burkina Faso, Greece, Mexico, Angola, Zimbabwe, Canada, the United States, and other countries and regions. In addition to large corn sheller equipment, we also have small corn threshers and multifunctional corn threshers for sale.

Working principle of maize sheller machine

The working principle of the corn sheller equipment is simple.

- Corn is fed into the thresher via the conveyor; the corn cobs enter the threshing chamber.

- Inside the threshing chamber, the corn is threshed and separated. Kernels, along with a small amount of impurities, fall through the concave board into the stirring drum.

- The mixed grains pass through the stirring drum and elevator to the cleaning sieve, where the mesh removes impurities smaller than the grains.

- Grains and main impurities move along the sieve surface toward the discharge outlet.

- When the grains reach the absorber, small impurities are sucked out, and clean grains enter the grain collection device.

- The threshed corn cobs are discharged from the straw outlet.

The diagram of the corn threshing machine

The reasonable design of the corn thresher machine is mainly composed of a conveyor belt, dust outlet, corncob outlet, grain delivery pipe, motor, and two tires. The specific parts location diagram is shown below.

- Conveyor belt: Responsible for continuously and evenly feeding the corn into the sheller, saving labor.

- Dust outlet: Discharges corn husk scraps, dust, and light impurities produced during the shelling process, ensuring the cleanliness of the kernels.

- Corn cob outlet: Specifically used to discharge the separated corn cobs after shelling.

- Corn discharge pipe: Smoothly outputs the corn kernels after shelling.

- Motor: Provides power for the whole machine, driving the shelling drum, fan, and conveying system.

Main advantages of the Taizy corn threshing machine

- High capacity: Equipped with a 15 HP high-power motor to drive the shelling device, it can process 4–6 tons of corn per hour.

- High Performance: Threshing rate up to 99.5%, loss rate below 2%, breakage rate below 1.5%, and impurity rate below 1%.

- High automation: The machine can be equipped with an elevator feeder and conveyor belt to achieve continuous operation.

- Powerful performance: Driven by a 7.5 kW motor or a diesel engine, it supports continuous threshing and adapts to different working environments.

- Thorough separation: Corn kernels and cobs are completely separated, with high kernel integrity and a low breakage rate.

- Durable structure: Made mostly of full steel construction, ensuring a long service life.

- Versatile use: Suitable not only for fresh corn but also for dry corn, seed corn, and different varieties.

- The design of the hoist and conveyor belt can save a lot of manpower, and it can also improve production efficiency.

- Feeding at a uniform speed will not cause machine blockage.

- Clean corn kernels can be directly sent to the storage bin through the grain delivery pipe.

- Customizable Sieve: Can be flexibly adjusted according to corn variety, kernel size, and working conditions, enhancing threshing efficiency, output quality, and extending the equipment’s service life.

Specifications of large corn sheller machine

| Model | 5TY-80A | 5TY-80B(with elevating feeder) | 5TY-80C (with conveyor) | 5TY-80D (with elevating feeder and conveyor) |

| Capacity(t/h) | 4 (corn seeds) | 4(Corn seeds ) | 6(Corn seeds) | 6(Corn seeds) |

| Power | 15HP diesel engine or 7.5 KW motor | 15HP diesel engine or 7.5 KW motor | 15HP diesel engine or 7.5 KW motor | 15HP diesel engine or 7.5 KW motor |

| Breakage rate | ≤1.5% | ≤1.5% | ≤1.5% | ≤1.5% |

| Threshing rate | ≥99.5% | ≥99.5% | ≥99.5% | ≥99.5% |

| Loss rate | ≤2.0% | ≤2.0% | ≤2.0% | ≤2.0% |

| Impurity rate | ≤1.0% | ≤1.0% | ≤1.0% | ≤1.0% |

| Weight | 200kg | 230kg | 320kg | 350kg |

| Size(mm) | 2360*1360*1480 | 2360*1360*2000 | 3860*1360*1480 | 3860*1360*2480 |

It can be seen from the figure that the capacity of the large corn threshing machine is 4-6 tons per hour. You can choose machines with a hoist and feeder and machines without a hoist and feeder. But the threshing rate, breakage rate, and loss rate of the machine are all the same. You can choose according to your actual needs.

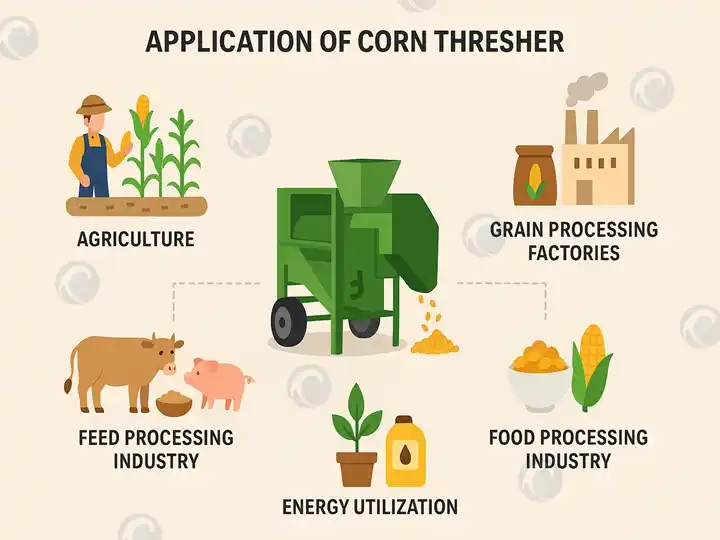

Applications of the corn thresher

- Fresh Corn: Efficiently threshes and separates kernels from freshly harvested corn cobs.

- Dry Corn: Suitable for processing dry corn for storage or further use.

- Seed Corn: Can handle seed corn, ensuring high kernel integrity and low breakage.

- Variety Adaptability: Works with different corn varieties, including small or large cobs.

- Agricultural Scale: Ideal for small to medium farms, cooperative threshing operations, and pilot production lines.

Installation and commissioning

- Diesel Engine Installation: Install the diesel engine on the frame, adjusting the screw length and the main shaft belt tension. The frame has adjustment screws; loosen them to raise the engine, relaxing the belt. Start the diesel engine under no-load conditions.

- Belt Check: Check the tension of the belts on the main shaft, screw conveyor, elevator, and fan. The tension should be moderate. If the elevator belt is too loose, corn may not be lifted smoothly, causing blockages in the lower machine shell.

- Vibrating Sieve Angle Adjustment: Adjust the angle of the vibrating sieve by changing the height of the supporting frames on both sides to control the impurity removal speed.

- Air Duct Installation: The air duct length should be approximately 3–5 meters and well-ventilated. Use a disposable breathable cloth bag to ensure smooth airflow and proper removal of impurities.

- Impurity Outlet: The area below the vibrating sieve serves as the impurity outlet, where most impurities are discharged. Long cloth bags can be tied at the outlet to collect impurities.

- Machine Support Adjustment: Before operation, adjust the height of the diesel engine’s lower support rod so that the two wheels are almost off the ground, ensuring stable machine operation.

Roubleshooting of the corn thresher

Lower Machine Shell Blockage

Cause 1: Elevator belt too loose, slowing down corn lifting.

Cause 2: The Drive wheel belt is too loose, preventing the drive wheel from rotating.

Solution: Tighten both the elevator belt and the drive wheel belt.

Incomplete Threshing

Cause: Threshing degree insufficient.

Solution: The machine has two discharge devices; removing one or both can improve threshing efficiency.

Corn Cobs Too Brittle

Cause 1: Corn cobs are naturally brittle or rotten.

Cause 2: Corn cobs discharged too slowly.

Cause 3: Vibrating sieve angle too low.

Solution: Add 1–2 discharge devices to speed up, and/or increase the vibrating sieve angle.

Impurities Not Fully Removed

Cause: The cloth bag has poor breathability, restricting airflow.

Solution: Replace with a more breathable cloth bag.

The price corn threshing machine

The price of a corn thresher is affected by many factors, such as output, brand, quality, shipping cost, and country of origin, etc. Therefore, if you want to know the price of the maize thresher machine, please tell us your needs. Then our sales will contact you as soon as possible and inform you of the specific price of the machine. In addition, if you want to get the best electric corn sheller, you should first pay attention to the quality and capacity of the corn sheller machine, and the price is the second concern. Only in this way can we buy a high-quality corn threshing machine.