Sweet Corn Thresher Machine

| Model | SL-368 |

| Capacity | 400-500kg/h |

| Size (mm) | 1320(L)*620(W)*1250(H) |

| Voltage | 220V,1 phase |

| Power | 2.2kw |

You can now ask our project managers for technical details

Taizy sweet corn thresher machine is a piece of agricultural equipment designed to remove the kernels from sweet corn cobs quickly and efficiently. It automates the process of separating the corn kernels from the cob, saving time and labor compared to manual methods.

This small sweet corn shelling machine is specially designed for fresh corn, sweet corn, and waxy corn. It can process 400–500 kg per hour with excellent performance. The kernels remain intact, and the shelling rate can reach over 98%.

It is widely used in food processing fields such as frozen corn, canned corn, and packaged corn kernels. It is an ideal machine for modern corn processing plants, food factories, and agricultural processors.

The Taizy machine features a compact structure, easy operation, and clean shelling. It is popular in countries and regions such as Canada, the United States, Brazil, Mexico, and South Africa.

What Are the Benefits of Sweet Corn Thresher Machine?

Time-saving

With a sweet corn thresher machine, You can process 400-500kg of sweet corn in less than an hour. This allows you to meet the demands of your customers or market more effectively.

Stainless Steel Body

All parts in contact with materials are made of 304 food-grade stainless steel. It is rust-resistant, easy to clean, and meets food safety standards.

High-Efficiency Shelling Drum

Equipped with special spiral blades and stable drum speed, it ensures a shelling rate of over 98% with a kernel breakage rate below 1%.

Adjustable Blade Gap

The gap can be adjusted freely according to the diameter of corn cobs, ensuring complete shelling for different sweet corn varieties.

Automatic Separation System

Automatically separates corn kernels from cobs after shelling—no secondary screening required.

Stable Motor Performance

Powered by a 2.2 kW copper-core motor, offering strong power, low energy consumption, and quiet operation—ideal for continuous work.

The Structure of Sweet Corn Thresher

Sweet Corn Sheller for Sale

| Model | SL-268 | SL-368 (with conveyor belt) |

| Capacity | 400-500kg/h | 400-500kg/h |

| Size (mm) | 700(L)*620(W)*1250(H) | 1320(L)*620(W)*1250(H) |

| Voltage | 220V,1 phase | 220V,1 phase |

| Power | 2.2kw | 2.2kw |

The above are two hot-selling sweet corn threshers. The difference between the 2 machines is that one comes with a conveyor belt and the other does not. So far, the machine has been exported to countries such as the United States, Egypt, Canada, the Philippines, Singapore, and Indonesia.

If you are interested in this machine, please feel free to contact us. As a professional sweet corn sheller supplier, we will provide you with the best machine. In addition, we have a large dry corn threshing machine and corn grits milling machine for sale.

How Does a Sweet Corn Thresher Machine Work?

Without Conveyor (Manual Feeding)

- Feeding: The operator places each corn cob into the feed inlet manually, with the head facing forward into the shelling chamber.

- Shelling Process: High-strength blades rotate at high speed, closely cutting along the surface of the corn cob to remove kernels neatly. The cutting depth can be adjusted to suit different corn varieties and maturity levels.

- Separation and Collection: A combination of a vibrating screen and blower separates the kernels from the cobs and debris. The kernels fall intact from the discharge outlet.

- Control System: Equipped with variable frequency speed control, allowing adjustment of blade speed and shelling depth. In case of clogging, the machine can run in reverse to clear materials safely and reliably.

With Conveyor (Automatic Feeding)

- Feeding: The stainless-steel chain conveyor automatically delivers corn cobs into the shelling chamber at an average speed of about 15 m/min. It can feed around 75 corn cobs per minute, with a single-machine output of 300–350 kg/h.

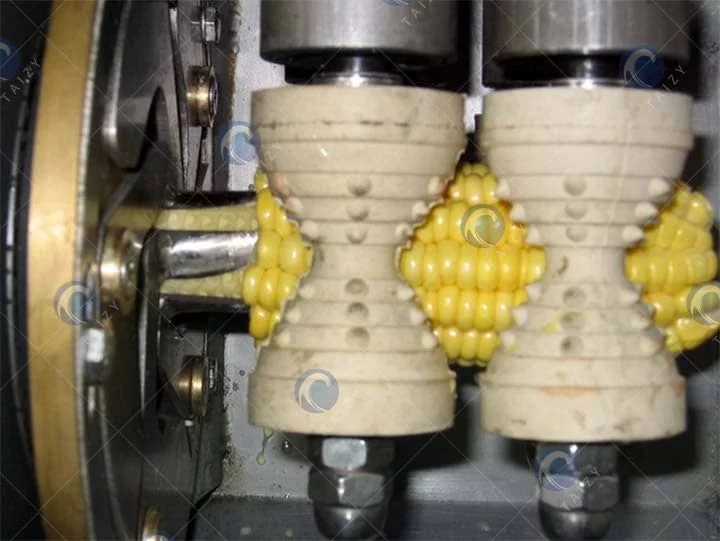

- Feeding and Clamping: Rubber rollers automatically clamp and guide the corn cobs into the blade area. The soft, flexible rubber material prevents the corn from being crushed or leaking juice.

- Shelling and Separation: Five high-strength blades rotate counterclockwise at high speed to evenly cut off the kernels with smooth and flat cuts. The shelling depth is adjustable. Inside the machine, a vibrating screen and blower automatically separate the kernels from the cobs.

- Cob Discharge: The discharge wheels work together with the toothed disc cutter to discharge the corn cobs steadily and prevent clogging.

- Electrical Control: A frequency control system allows adjustment of speed and shelling depth, ensuring high-speed, efficient, and low-damage operation.

Applicable Industries

You can use the sweet corn shelling machine in food & beverage factories, hotels, farms, restaurants, home use, food shops, and others. This is because sweet corn can be made into foods such as canned sweet corn, frozen sweet corn, and sweet corn health drinks.

How to Find a High-Quality Sweet Corn Thresher Machine?

Capacity

Determine the amount of corn you need to process regularly and choose a machine with a corresponding capacity. Consider both current and future needs to avoid outgrowing the machine too quickly.

Power Source

Sheller for sweet corn is available in various power options, including electric, diesel, and tractor-driven models. Choose the one that aligns with your available resources and operational requirements.

Size and Portability

Depending on your available space and mobility needs, select a machine that fits your specific requirements. Consider whether you need a stationary or mobile unit for your corn processing operation.

Easy Maintenance

Opt for a machine that is designed for easy cleaning and maintenance. This will save you time and effort in the long run, ensuring smooth operation and longevity.

Durable Construction

Choose a thresher machine made of high-quality materials that can withstand the rigors of continuous use. Robust construction ensures reliability and longevity, minimizing downtime.

Maintenance and Precautions

After each operation, clean the cutter disc and the feeding/discharging parts to prevent corn residue buildup that could affect cutting performance.

Usage Recommendations:

- Keep the corn ears whole; do not cut off the top.

- The corn length should be no less than 8 cm.

Cutting Depth Adjustment:

- A stainless-steel adjustment ring on the cutter head controls the cutting depth.

- Loosen the five screws: turn the ring clockwise for shallower cutting, counterclockwise for deeper cutting.

- After adjusting the ring, set the inverter frequency—start from 40 Hz, then gradually increase until the cutting is smooth and depth is proper (normally not exceeding 60 Hz).

Blade Replacement:

- All five blades must be replaced at the same time; mixing old and new blades is prohibited.

- After tightening the blade screws, manually move each blade to ensure it swings freely.

- If corn residue blocks blade movement, clean the cutter head promptly.

Maintenance Tips for Fresh Sweet Corn Sheller

To ensure the smooth operation and longevity of your fresh sweet corn sheller, follow these maintenance tips:

- Regular cleaning. Clean the machine thoroughly after each use to remove any residue or debris. Pay special attention to the blades, vibrating screen, and air blower to ensure they are free from clogs or build-up.

- Lubrication. Apply lubricant to the moving parts of the machine as recommended by the manufacturer. This helps reduce friction and prolongs the lifespan of the machine.

- Inspection. Regularly inspect the machine for any signs of wear and tear, loose components, or damage. Address any issues promptly to prevent further damage and ensure safe operation.

- Belt and chain maintenance. Check the belts and chains for proper tension and alignment. Adjust or replace them as necessary to maintain optimal performance.

- Electrical components. If your fresh sweet corn sheller is electric-powered, ensure that the electrical connections are secure and in good condition. Periodically inspect the wires and connectors for any signs of damage.

- Safety precautions. Always follow the manufacturer’s safety guidelines and instructions. Keep the machine away from water or moisture to prevent electrical hazards. Disconnect the power source before performing any maintenance or repairs.

Future Trends in Sweet Corn Thresher Machine Technology

- Automation and smart features. Sweet corn thresher machines are likely to incorporate more automation and smart technologies. This may include features such as advanced sensors, self-adjusting settings, and data monitoring for improved efficiency and performance.

- Energy-efficient designs. Manufacturers are increasingly focusing on developing energy-efficient machines to reduce operational costs and environmental impact. Expect to see more energy-saving technologies integrated into sweet corn thresher machines.

- Integration with digital platforms. As connectivity becomes more prevalent in agriculture, sweet corn thresher machines may integrate with digital platforms for remote monitoring, data analysis, and precision farming practices. This can lead to optimized performance and better decision-making.

- Enhanced safety features. Manufacturers will continue to prioritize safety by implementing advanced safety features and systems. This may include improved emergency stops, enhanced guarding mechanisms, and real-time monitoring for potential hazards.

The sweet corn thresher machine is an essential tool for corn processing, offering numerous benefits such as time-saving, increased productivity, and improved corn quality.

When choosing a machine, consider factors like capacity, power source, and durability. Proper maintenance, including regular cleaning and lubrication, is crucial for optimal performance and longevity.

As technology evolves, future sweet corn thresher machines may incorporate automation, energy efficiency, and enhanced safety features. If you need this machine, please feel free to contact us.

Our Certificates

Sweet Corn Thresher Machine – FAQ

What types of corn can the sweet corn thresher process?

The machine is mainly designed for fresh, sweet, and glutinous corn, ensuring the kernels remain intact and undamaged. It is not suitable for dry or mature hard corn.

What is the production capacity of the machine?

Depending on the model, the capacity ranges from 300–500 kg/h.

The conveyor-type model allows continuous feeding, increasing efficiency and saving about 30% labor.

Will the kernels be damaged during threshing?

No. The machine uses flexible rubber rollers and adjustable cutting blades. The kernels are cut smoothly and neatly, with a breakage rate below 2%.

How can I adjust the threshing depth?

The threshing depth can be adjusted by changing the blade clearance or rotating speed via the inverter control panel, making it suitable for different corn varieties and ripeness levels.

What materials is the machine made of? Is it rust-proof?

The key components are made of stainless steel and food-grade rubber, ensuring corrosion resistance, easy cleaning, and compliance with food hygiene standards.

What’s the difference between the conveyor-type and manual models?

The conveyor-type model feeds corn automatically and is ideal for medium or large-scale factories.

The manual model requires hand feeding and is suitable for small-scale or trial production.

How should I clean and maintain the machine?

After shutting down and cutting off power, rinse the threshing chamber and conveyor with clean water.

Check blade wear regularly and apply lubrication. Dry the parts after cleaning to prevent rust.

What should I do if the corn gets jammed or stuck?

The machine is equipped with a reverse rotation function.

Simply press the reverse button, and the blades will rotate backward to release the jam safely.

What are the power requirements?

The machine operates on 220V single-phase electricity with a 2.2 kW motor, suitable for both household and industrial power sources.

Can this machine be integrated into a production line?

Yes. The sweet corn thresher can be connected with conveyor belts, washing machines, freezing systems, and packaging machines to form a complete sweet corn processing line.