Corn Silage Harvester | Straw Harvester

| Model | TZ-1400/TZ-1800 |

| Type | Wheeled/Tracked |

| Horsepower | 140-180HP |

| Rows | Single row |

| Cutting Width | 1400 mm |

| Chopping Length | 1400 mm |

| Working Efficiency | 0.66–1.32 acres/hour |

| Discharge Height | 3–5 m |

| Fuel Consumption | 12–18 L/hour |

| Suitable Terrain | Hills, soft soil, wetlands, and mountainous farmland |

You can now ask our project managers for technical details

The Taizy self-propelled corn silage harvester is a high-efficiency agricultural machine designed specifically for silage harvesting. It works by using internal blades to chop corn stalks into small pieces.

This model is suitable not only for harvesting corn silage but also for cutting and chopping crops like sorghum and forage grass, completing harvesting, chopping, and loading in a single pass.

The machine features a reasonable design and easy operation, equipped with a 150~180HP engine for strong power, significantly improving feed harvesting efficiency. It uses a hydraulic drive for smooth power, flexible operation, and multifunctional control, making it simple to operate.

This series of harvesters comes in both wheeled and tracked versions, suitable for flat plains, hills, mountains, and even tropical rainforest terrain.

Types of corn silage harvester

Wheeled

Work Video

Tracked

Work Video

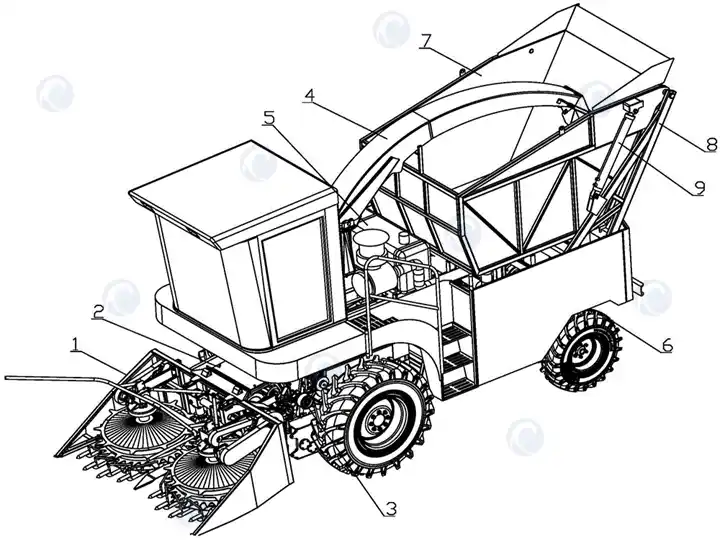

Structure of corn silage harvester

The self-propelled corn silage harvester mainly consists of a header system, a conveying system, a chopping system, a collection/elevating system, a power system (engine + hydraulic system), and a driving control system. All parts work together to harvest, chop, and transport corn silage efficiently.

Working principle of the corn silage harvester

- Header Harvesting: The front header cuts the corn stalks and feeds the whole plant into the machine.

- Conveying: The harvested corn is transported into the chopping system by a conveyor chain or auger.

- Chopping: Rotating knives or chopping rollers cut the corn stalks and cobs into uniform pieces.

- Lifting & Discharging: The chopped silage is lifted and discharged into a trailer or storage bin via an elevator or conveyor.

- Power & Control: The engine provides power, while the hydraulic system controls the header height, conveyor speed, and chopping operation.

Corn forage harvester for sale

We offer two models of corn forage harvester: TZ-1400 and TZ-1800

TZ-1400

| Parameter | Specification |

|---|---|

| Model | TZ-1400 |

| Type | Wheeled |

| Engine Power | ≥140 HP Diesel Engine |

| Rows | Single row |

| Cutting Width | 1400 mm |

| Chopping Length | 12–22 mm (adjustable) |

| Working Efficiency | 4–6 mu/hour |

| Discharge Height | 3–5 m |

| Tire Size | Front: 14.9-28 / Rear: 10.0-75-15 |

| Fuel Consumption | 12–16 L/hour |

| Suitable Terrain | Plains, hard farmland, fields, and road transport |

TZ-1800

| Parameter | Specification |

|---|---|

| Model | TZ-1800 |

| Type | Tracked |

| Engine Power | ≥180 HP Diesel Engine |

| Rows | Single row |

| Cutting Width | 1800 mm |

| Chopping Length | 12–22 mm (adjustable) |

| Working Efficiency | 5–8 mu/hour |

| Discharge Height | 3–5 m |

| Track Size | 450 mm Rubber Tracks |

| Fuel Consumption | 14–18 L/hour |

| Suitable Terrain | Hills, soft soil, wetlands, and mountainous farmland |

Both models of corn forage harvester can harvest crops up to 2–3 meters in height.

In addition, we also have corn processing machines such as corn harvesters and a variety of corn mill grinders for sale.

Features of the corn straw harvester

- Multifunctional. A corn silage harvester is a machine that integrates harvesting, cutting, crushing, and collecting. It really realizes one machine with multiple functions.

- The operation method is simple. Only one person is required to drive the tractor.

- The straw, after being cut and crushed by the corn silage harvester, can be recycled directly.

- The high degree of automation. The hydraulic device can easily unload the crushed corn stover.

- The hydraulic transmission device can easily control the running speed of the machine.

- The corn forage harvester blades are made of high-strength material and have the characteristics of strong wear resistance.

- The recovery rate is as high as 95%

- Fully hydraulic control with a small turning radius, making operation easy and flexible.

- Harvests without row spacing and can handle lodged (fallen) crops.

Uses of corn forage harvester

The machine is suitable for crushing and recycling various crop straws. Corn straw, cotton straw, banana straw, sorghum straw, wheat straw, and grass materials can all be recycled with this trailed silage harvester. The crushed straw can be directly returned to the field or used as animal feed.

How to use the corn silage harvester correctly?

- Preparation: Check all mechanical parts, the electrical system, and the hydraulic system before use, and preheat the machine.

- Loading Feed: Place the silage pile in front of the harvesting path. Avoid stacking it too high to ensure smooth harvesting.

- Starting the Machine: Turn on the power and start the machine. Monitor its operation and stop immediately if any abnormality occurs.

- Adjusting Header Height: Set the header height according to the feed height to ensure uniform harvesting.

- Harvesting: The operator controls the machine forward and backward using the joystick, maintaining stability and safely harvesting the silage.

- Collecting Feed: The chopped silage is conveyed into the collection system. Clean regularly to ensure smooth operation.

- Ending Operation: After harvesting, turn off the machine and transport the collected silage to the designated location.

- Cleaning & Maintenance: Clean debris from the machine surface, check worn parts, and replace them in time to keep the equipment in good condition.

Partnering with Taizy

Partnering with Taizy, you can achieve efficient, reliable, and high-quality corn silage harvesting. Our self-propelled harvesters are designed to handle a variety of crops and terrains, ensuring smooth operation, uniform chopping, and maximum feed yield. Whether for small farms or large-scale operations, Taizy’s Corn Silage Harvesters deliver the performance and durability you can trust, making silage harvesting easier and more productive than ever.