Комбайн для уборки кукурузного силоса | Соломоуборочный комбайн

| Модель | ТЗ-1650 |

| Производительность (акр/ч) | ≈1,1 |

| Лошадиные силы | 70-90 |

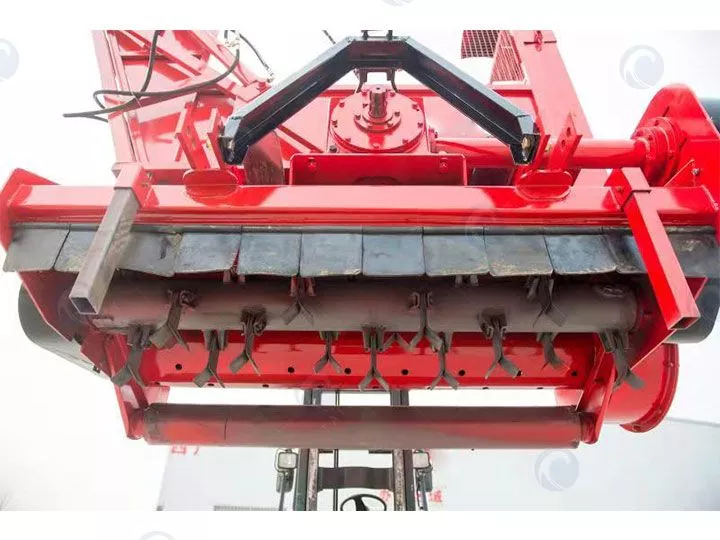

| Количество лезвий | 48 |

| Вес (кг) | 650 |

| Размер | 1,3x1,8x1,1 |

Теперь вы можете уточнить технические подробности у наших менеджеров проектов.

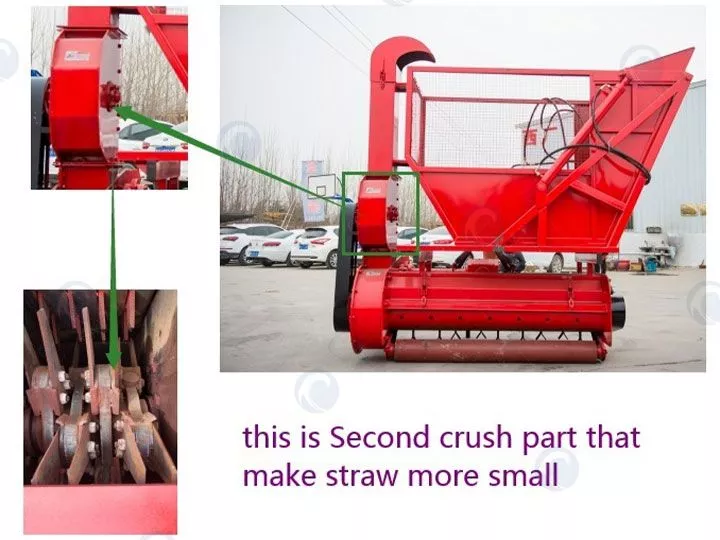

Комбайн для уборки кукурузного силоса — это, главным образом, машина, которая использует лезвия внутри машины для измельчения стеблей кукурузы на мелкие кусочки.

Он может измельчать и перерабатывать не только стебли кукурузы, но и солому различных культур, таких как стебли хлопка, стебли сорго и стебли подсолнечника. Переработанная кукурузная или зерновая солома может быть напрямую использована в качестве корма для животных.

Конструкция комбайна для уборки кукурузного силоса

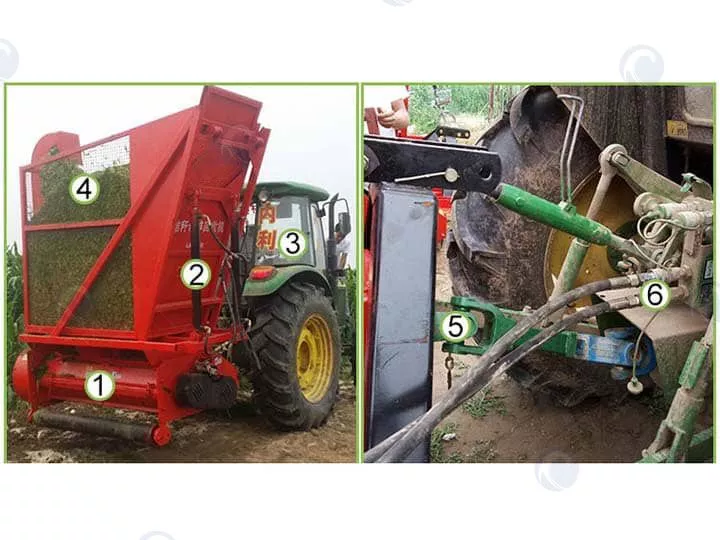

Машина состоит из рамы, устройства подвески, коробки передач, ящика для сбора стеблей кукурузы, привода ВОМ, разгрузочного окна, гидравлического разгрузочного устройства, вентилятора и других конструкций.

Как работает комбайн для уборки кукурузного силоса?

Сначала пользователю необходимо подсоединить комбайн для уборки кукурузного силоса к трактору. Во время работы лезвие внутри машины быстро срежет стебли кукурузы. Затем солома подается в секцию дробления машины. Затем измельченные стебли урожая вентиляторами транспортируются в мусорный бак. Наконец, гидравлическое устройство загружает и выгружает измельченную солому в трактор. Вот как работает комбайн для уборки кукурузного силоса.

Продам кукурузоуборочный комбайн

| Модель | Лошадиные силы | Вес (кг) | Производительность (акр/ч) | Размер | Количество лезвий |

| ТЗ-1000 | 40 | 400 | ≈0,6 | 1,3×1,7×1,1 | 30 |

| ТЗ-1300 | 50-60 | 450 | ≈0,8 | 1,3×1,7×1,1 | 32 |

| ТЗ-1500 | 60-80 | 550 | ≈0,9 | 1,3×1,8×1,1 | 42 |

| ТЗ-1650 | 70-90 | 650 | ≈1,1 | 1,3×1,8×1,1 | 48 |

| ТЗ-1800 | 90-100 | 720 | ≈1,1 | 2,1×1,3×1,1 | 54 |

| ТЗ-2000 | 100-120 | 820 | ≈1,6 | 2,1×1,3×1,1 | 60 |

Выше приведены только параметры некоторых прицепных силосоуборочных комбайнов. Кукурузное оборудование Taizy имеет множество машин с различной шириной резки, например, 1 м, 1,3 м, 1,5 м, 1,65 м, 1,8 м, 2 м, 2,2 м и 2,4 м. Клиенты могут выбирать в соответствии со своими потребностями. Кроме того, мы также можем предоставлять индивидуальные услуги в соответствии с реальной ситуацией клиентов. Кроме того, у нас также есть машины для переработки кукурузы, такие как кукурузоуборочные комбайны и разнообразные мельница для кукурузыпродается.

Особенности комбайна для уборки кукурузной соломы

- Многофункциональный. Комбайн для уборки кукурузного силоса — это машина, объединяющая уборку, резку, измельчение и сбор. Он действительно реализует одну машину с множеством функций.

- Метод работы прост. Для управления трактором требуется только один человек.

- Солома, срезанная и измельченная комбайном для уборки кукурузного силоса, может быть напрямую переработана.

- Высокая степень автоматизации. Гидравлическое устройство позволяет легко разгрузить измельченную кукурузную солому.

- Гидравлическое трансмиссионное устройство позволяет легко контролировать скорость работы машины.

- Лезвия кукурузоуборочного комбайна изготовлены из высокопрочного материала и обладают высокой износостойкостью.

- Скорость восстановления достигает 80%.

Использование кукурузоуборочного комбайна

Машина подходит для измельчения и переработки соломы различных культур. Кукурузная, хлопковая, банановая, сорго, пшеничная солома и травяные материалы могут быть переработаны с помощью этого прицепного силосоуборочного комбайна. Измельченную солому можно сразу вернуть на поле или использовать в качестве корма для животных.

Как правильно пользоваться кукурузоуборочным комбайном?

- Пользователь должен отрегулировать машину на высоте 20-50 см от земли. Это предотвращает повреждение подвеса.

- Подсоедините вал отбора мощности и проверните его 1-2 раза.

- Включите рабочий механизм и отпустите схватить медленно.

- При работе силосоуборочного комбайна количество рядов уборки следует определять в зависимости от плотности посева и мощности трактора.

- Обратите внимание, чтобы проверить, разблокировано ли выходное отверстие стеблей кукурузы, чтобы избежать засорения и нарушения нормальной работы. В случае возникновения нештатной ситуации немедленно остановите машину для проверки.

- Обратите внимание на проверку натяжения ремня во время рабочего процесса машины, чтобы не снизить скорость вращения вала фрезы и не повлиять на эффект дробления.

- Если вам необходимо перевернуть комбайн для уборки кукурузного силоса, его следует сначала поднять, затем развернуть, а затем опустить.

- Если во время работы машины слышен ненормальный шум, она должна немедленно прекратить работу.