How Efficient Are Modern Corn Shellers?

The TZ-1500 small corn sheller is designed for high efficiency, making it an ideal choice for family farms and small-scale operations. While modern corn shellers have significantly improved compared to traditional machines, how efficient are they really? In this article, we take a closer look at the TZ-1500 and its advantages in corn harvesting.

Limitations of Traditional Corn Shellers

Small traditional corn shellers often face several challenges:

- Low Processing Capacity: Many traditional machines can only shell a few hundred kilograms per hour, making them slow for larger harvests.

- Incomplete Shelling: Uneven shelling results in unprocessed cobs and a high kernel breakage rate, causing grain loss.

- Complex Operation: Most machines require skilled operators, making them less suitable for household farms or inexperienced users.

- These limitations mean farmers spend more time, labor, and resources to process the same amount of corn.

TZ-1500 Small Corn Sheller

The TZ-1500 addresses these common problems and offers significant advantages:

High Processing Capacity

Shells 1,500–2,000 kg of corn per hour, greatly reducing processing time compared to traditional small machines.

Clean and Low-Loss Shelling

Optimized drum design ensures a shelling rate over 98% with minimal kernel breakage. The built-in fan automatically removes dust and debris, producing clean, high-quality corn.

Flexible Power Options

Users can choose between a 2.2 kW electric motor or a gasoline engine, making it suitable for areas with limited electricity or off-grid farms.

Compact and Easy to Operate

Weighing only 65 kg and sized 440×400×800 mm, the TZ-1500 is portable, space-saving, and easy to operate—even for beginners.

Durable and Stable Performance

Made from high-quality steel with a reinforced rotor and sturdy frame, the machine runs smoothly with low vibration and long-term reliability.

Efficiency Comparison

| Feature | Traditional Small Corn Sheller | TZ-1500 Small Corn Sheller |

|---|---|---|

| Processing Capacity | 300–700 kg/h | 1,500–2,000 kg/h |

| Shelling Rate | 85–90% | ≥98% |

| Kernel Breakage | High | Low (<5%) |

| Ease of Use | Complex, skilled operator required | Simple, suitable for home use |

| Dust & Impurity Removal | None | Built-in fan ensures clean output |

The table clearly shows that the TZ-1500 small corn sheller outperforms traditional machines in capacity, shelling quality, kernel integrity, and user-friendliness.

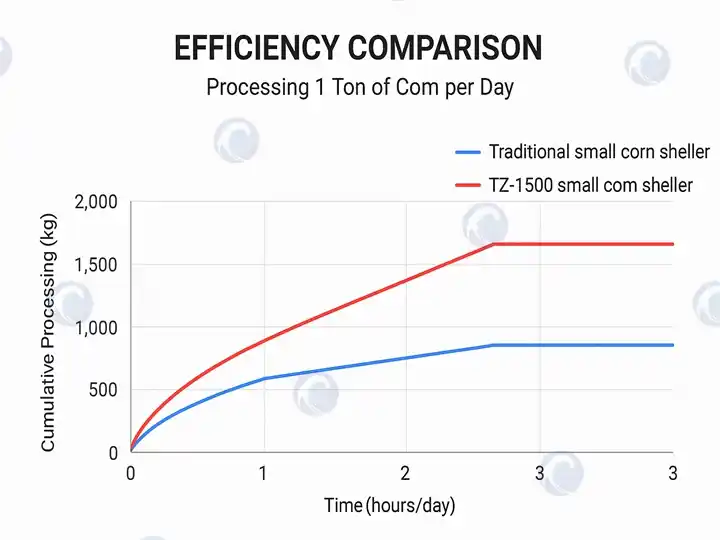

Efficiency Calculation – Example: Processing 1 Ton of Corn per Day

Line Chart Design Description

- X-axis: Working Time (hours/day)

- Y-axis: Cumulative Processing Amount (kg/day)

Assuming a total of 1,000 kg (1 ton) of corn per day, compare the time required for two machines to complete the task:

| Time (hours) | Traditional Small Corn Thresher | TZ-1500 Small Corn Thresher |

|---|---|---|

| 0 | 0 | 0 |

| 1 | 400 | 1,500 |

| 2 | 800 | 3,000 |

| 3 | 1,000 (complete) | 4,500 |

Note:

The TZ-1500 processes far more than 1 ton per day and can easily finish within a few hours, while the traditional small thresher takes about 2.5 hours to complete 1 ton. For chart display, the Y-axis can be scaled proportionally to 0–2,000 kg.

Chart Features:

- Blue line: Traditional small corn thresher, ~400–500 kg/h

- Red line: TZ-1500 small corn thresher, ~1,500–2,000 kg/h

The chart clearly shows that the TZ-1500 takes much less time to process 1 ton of corn.

Axis Labels:

- X-axis: Hours

- Y-axis: Cumulative Processing Amount (kg)

Cooperate with Taizy

Modern small corn shellers like the TZ-1500 are transforming small-scale corn harvesting. With high efficiency, clean shelling, flexible power options, and easy operation, the TZ-1500 allows farmers to process corn faster, reduce waste, and increase yield. For family farms or small-scale operations, this is a smart and practical investment.