Maize Grits Milling Machine | Corn Grit Machine

| Model | T3 |

| Power | 7.5kw+4kw |

| Capacity | 300-400kg/h |

| Size | 1400*2300*1300mm |

| Weight | 680kg |

| Production date | 7-15 working days |

| Warranty period | 12 months |

You can now ask our project managers for technical details

Taizy maize grits milling can make large corn grits, small corn grits, and corn flour at the same time. The corn grits made by this machine have a bright and clean color and high quality.

Depending on capacity and configuration, Shuliy offers five models of maize grits milling machines: T1, T2, T3, C2, and PH.

The best-selling T1 model can process 1,000 kg of maize grits per hour, with 350–450 kg of corn peeling and 350 kg of corn flour. The T3 model produces 300–400 kg per hour. We recommend the T1 and T3 models as the most popular options.

And the corn grits can be sold directly in supermarkets and grain/oil wholesale markets. So, this machine has a wide range of applications.

The advantages of the Taizy corn grits making machine

- You can get three corn products at the same time. With the help of our maize grits milling machine, you can get small maize grits, large corn grits, and corn flour.

- The high degree of automation. The corn grits making machine completes the process of cleaning, peeling, de-embryoing, de-rooting, crushing, grinding, grading, and polishing corn grits at one time.

- The finished product is clean. The T3 model is equipped with a dust extraction unit, and the resulting corn grits can be sold directly in supermarkets.

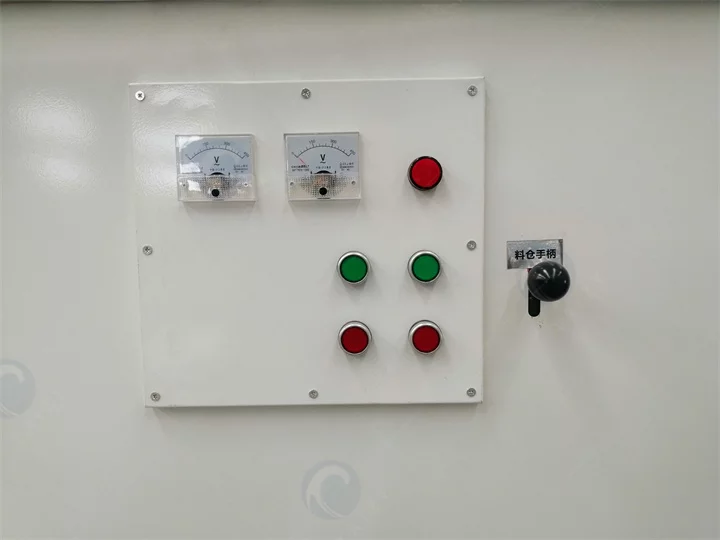

- Easy to operate. Push-button operation panel, easy to learn.

- Multiple models. We have 5 different types of machines for sale. It can meet a wide range of customer needs.

What are the types of maize milling machines?

As a professional corn processing equipment manufacturer, we have 5 different types of maize grits milling machines for sale. They are T1, T3, PH, PD2, and C2, respectively.

These five machines have different characteristics and advantages. Next, I will introduce these five machines to you in detail. Customers can choose according to their needs.

Type 1: T1 small maize grits milling machine

Features

- Power options: Electric motor or diesel engine

- Capacity: Corn peeling 350–450 kg/h; maize grits 1000 kg/h; corn flour 350 kg/h

- Main shaft speed: 1150 rpm

- Configuration: Single machine; must peel before grinding; cannot peel and make grits simultaneously

- Material/Structure: Standard carbon steel body; easy to operate

- Suitable for: Small farms and small grain processing plants

T1 Small maize grits milling machine – technical parameters

| Model | T1 |

| Corn peeling | 200kg/h |

| Making corn grits | 1000kg/h |

| Making corn flour | 350kg/h |

| Rated voltage | 380v |

| Power | 7.5kw |

| Spindle speed | 1150r/min |

Type 2: T3 large corn grit machine

Features

- Power options: Dual motors (7.5 kW + 4 kW)

- Capacity: 300–400 kg/h

- Dimensions: 1400 × 2300 × 1300 mm

- Weight: 680 kg

- Configuration: Can peel and make grits at the same time; equipped with cyclone separator for corn husks and dust

- Material/Structure: Carbon steel body; efficient operation

- Suitable for: Medium-capacity processing plants with high product cleanliness requirements

T3 Large corn grit machine – technical parameters

| Model | T3 |

| Power | 7.5kw+4kw |

| Capacity | 300-400kg/h |

| Size | 1400*2300*1300mm |

| Weight | 680kg |

Type 3: PD2 maize grits milling machine

Features

- Power options: 15 kW motor

- Capacity: 400 kg/h

- Dimensions: 265 × 125 × 320 cm

- Configuration: Fully automatic system with dual elevators + peeling & grits machine; can include cleaner, screw conveyor, and grain silo

- Material/Structure: All-steel body; durable and reliable

- Suitable for: Medium to large processing plants with high output needs; can form a small maize grits production line

PD2 maize grits milling machine – technical parameters

| Model | PD2 |

| Power | 15kw |

| Capacity | 400kg/h |

| Size | 265*125*320cm |

Type 4: PH corn grits making machine

Features

- Power options: 11 kW motor

- Capacity: 300 kg/h

- Dimensions: 200 × 130 × 65 cm

- Configuration: Similar to T3 but without a dust removal system

- Material/Structure: Compact, durable, easy to operate

- Suitable for: Budget-conscious clients or those with moderate product cleanliness requirements

PH corn grits making machine – technical parameters

| Model | PH |

| Capacity | 300kg/h |

| Power | 11kw |

| Size | 200*130*65cm |

Type 5: C2 corn grits making machine

Features

- Power options: Motor (similar power to PH)

- Capacity: ~300 kg/h (similar to PH)

- Dimensions/Weight: Similar to PH

- Configuration: Simplified version for economical clients

- Material/Structure: Standard carbon steel body

- Suitable for: Small farms or budget-limited grain processing plants

Comparison of five corn maize grits machine models

Similarities

- All can process maize into large grits, small grits, and corn flour.

- Basic components are similar: hopper, peeling system, grinding system, and outlet.

- Suitable for small to medium grain processing plants, and relatively easy to operate.

- Power options: electric motor or diesel engine (some models have dual motors or a fixed motor setup).

Differences

- T1: Single machine; must peel before grinding; moderate capacity; flexible power options.

- T3: Dual-motor design; can peel and grind at the same time; equipped with cyclone separator for cleaner products; high efficiency.

- PH: Similar to T3 but without dust removal; lower price; compact; efficient.

- C2: Similar to PH in function and appearance; lower price; suitable for budget-conscious clients.

- PD2: Equipped with dual elevators and cleaner; fully automatic; high capacity with clean output; can form a small production line for high-output needs.

Concise comparison table of maize grits milling machine models

| Model | Power (kW) | Capacity (kg/h) | Special Features | Price / Suitability |

|---|---|---|---|---|

| T1 | 7.5 | Peeling 350 Grits 1000 Flour 350 | Single machine manual feeding | Medium |

| T3 | 7.5 + 4 | 300–400 | Cyclone separator | Medium–High |

| PH | 11 | 300 | No dust removal | Low |

| C2 | Similar to PH | Similar to PH | Simplified functions | Low |

| PD2 | 15 | 400 | Cleaner and dual elevators | High |

Buying guide

- For high efficiency and clean output → choose T3 or PD2.

- For a limited budget → choose PH or C2.

- For flexible operation and step-by-step processing → choose T1.

What is the maize grits manufacturing process?

After learning about the 5 different types of corn grits making machines, do you want to know how these machines work? Next, I will introduce you in detail.

- First, we need to pour the corn from the hopper into the peeling room of the corn grits machine. The corn is pushed to the peeling chamber by the propeller‘s rotation.

- In the peeling chamber, the density between corns will increase due to the gradual reduction of the working chamber volume and the influence of mechanical resistance.

- The corn husk will come off due to the squeezing and friction inside the machine. Then the corn kernels will enter the crushing system.

- Then it enters the grading system to obtain corn flour, large corn grits, and small corn grits through automatic separation.

- Finally, the dust is cleaned by the air net dust removal system. Then we can get clean products.

How to choose the right corn grits machine?

Based on capacity

- Small-scale households or farmers: Low daily output; T1 or C2 models are sufficient.

- Medium-scale processing: Daily output 300–400 kg/h; T3 or PH models are efficient with cleaner products.

- Large-scale processing / small production line: High daily output and automation needed; choose PD2. It can be equipped with a cleaner and elevators to form a complete processing line.

Based on the budget

- Low budget: C2 or PH models; affordable and functional.

- Medium budget: T1 or T3 models; balance efficiency and product quality.

- High budget/production line investment: PD2; can form a small maize grits production line with highest capacity and efficiency.

Based on additional features

- Dust removal or separator needed? T3 has a cyclone separator; PD2 can be equipped with a cleaner for cleaner products.

- Connection to conveyor or grain silo needed? PD2 can work with screw conveyors, elevators, and cleaners to form a complete production line.

Applications of corn grits

Corn grits are a versatile ingredient with numerous applications across various industries.

In the food processing industry, corn grits are commonly used to produce a wide range of products such as breakfast cereals, snacks, cornmeal, tortillas, and bakery items.

Additionally, corn grits serve as a crucial component in the brewing industry, where they are used as adjuncts in beer production to enhance flavor and consistency.

Beyond human consumption, corn grits are also utilized in the animal feed industry, providing a valuable source of carbohydrates and energy in livestock feed formulations.

Choosing the right maize grits milling machine

When choosing the maize grits making machine, you need to consider several factors. First, it is important to assess production needs, including expected production volume, machine capacity, and specific product specifications.

Second, the budget is also a key factor. You need to consider both the purchase cost as well as the long-term operating and maintenance costs.

The brand is also an important consideration. Choosing a reputable brand with high market ratings can increase the reliability and durability of the machine.

Finally, the quality of after-sales service should not be overlooked.

Taizy Machinery is a professional corn machinery manufacturer in China. So far, our corn grits making machine has been exported to the United States, Brazil, Argentina, India, Mexico, the Philippines, and many other countries and regions.

If you are looking for high quality maize grits milling machine, please feel free to contact us.

The customer in the Philippines ordered a T1 maize grits milling machine

In June 2022, the Philippine customer Mr. Nathan ordered a T1-type corn grits machine. According to the customer, he has a farm and wants to buy a maize grits milling machine to help him produce corn agricultural and sideline products.

Through communication with our sales, he decided to buy a machine from our company. The machine is now creating value on the customer’s farm.