Fresh Corn Vacuum Packing Machine

| Model | TZ-500/2H |

| Power | 0.9kw |

| Material | SS304 |

| Vacuum pump size | 20 |

| Lid material | Acrylic |

| Weight | 80kg |

| Size(mm) | 750*650*1020 |

| CBM | 0.5 |

You can now ask our project managers for technical details

The fresh corn vacuum packing machine is a compact and efficient device designed for vacuum sealing fresh corn, helping to extend its shelf life. The machine supports a maximum chamber volume of 0.65 CM³.

The machine body is made of food-grade stainless steel 304, featuring a smooth surface that is corrosion-resistant and easy to clean.

This vacuum pack machines is not only ideal for fresh corn, but also suitable for packaging meat, dried goods, vegetables, fruits, electronic components, hardware, textiles, and more. It provides excellent protection against oxidation, mold, moisture, and spoilage—ensuring freshness and quality.

Shuliy’s subsidiary, Taizy, specializes in food machinery. With 14 years of experience in R&D, we are a leading force in China’s packaging industry. Our machines are exported to over 40 countries across Europe, South Asia, the Middle East, Africa, Australia, and the Americas. We also maintain close cooperation with domestic partners and food factories. Global buyers are welcome to visit and discuss business with us.

Why Vacuum Pack Fresh Corn Cobs?

Vacuum packing fresh corn cobs offers several key benefits:

Extended Shelf Life

Fresh corn is rich in moisture and sugars, making it prone to spoilage from microbes and oxygen. Vacuum sealing removes air—especially oxygen—inside the bag, slowing down microbial growth and oxidation. This significantly prolongs freshness.

Prevents Oxidation and Discoloration

Natural enzymes and nutrients in corn can oxidize in the presence of air, causing color fading and poor taste. Vacuum packaging limits oxygen exposure, helping maintain the corn’s bright color and natural flavor.

Inhibits Bacterial and Mold Growth

The oxygen-free environment inside the vacuum-sealed bag prevents the growth of most bacteria and molds, improving food safety and reducing spoilage risks.

Locks in Moisture and Freshness

Vacuum sealing keeps the moisture inside the corn, preventing it from drying out. This ensures a juicy, tender texture and a better eating experience.

Improves Storage and Transport Efficiency

Vacuum-packed corn takes up less space and is less prone to damage during transport. It’s ideal for cold chain logistics and long-term storage with reduced loss.

Enhances Product Appeal and Market Competitiveness

Vacuum packaging gives the product a more premium and professional look, making it more attractive to customers in supermarkets and markets, and boosting buyer confidence.

Working Principle of the Fresh Corn Vacuum Packing Machine

The fresh corn vacuum packing machine works by using a vacuum pump to remove air from inside the packaging bag, creating a vacuum environment. This inhibits the growth and reproduction of microorganisms and prevents food oxidation and spoilage. The main process includes three stages: vacuuming, heat sealing, and air release.

- Vacuum Stage

When the machine runs, the vacuum pump extracts air from the packaging bag, creating a low-pressure environment. Once the vacuum gauge reaches the preset level, the pump stops. The reduced oxygen inside the bag slows microbial growth.

- Heat Sealing Stage

After vacuuming, the machine seals the bag using a heat press. The heat sealing chamber pushes down the sealing bar with pressure while heating the sealing strip, ensuring an airtight seal.

- Air Release Stage

Once sealed, air is released back into the bag via a solenoid valve, bringing the vacuum gauge back to zero and completing the cycle.

The machine usually features an automatic control system, allowing preset vacuum time, sealing temperature, and other parameters to suit different bag sizes.

Advantages of Shuliy Fresh Corn Single-Chamber Vacuum Packing Machine

- Wide Application: Not only suitable for fresh corn, but also for vacuum packing various foods, fruits and vegetables, electronics, and metal parts—one machine, multiple uses.

- No Special Vacuum Bags Needed: Compatible with smooth bags, zipper bags, aluminum-plated bags, pure aluminum bags, printed bags, handle bags, and more.

- Smarter Operation: Integrated intelligent control panel makes packaging easier and more convenient.

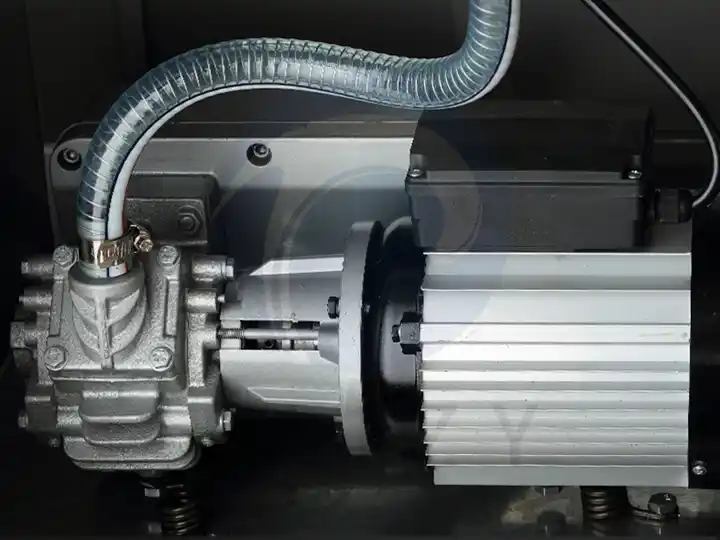

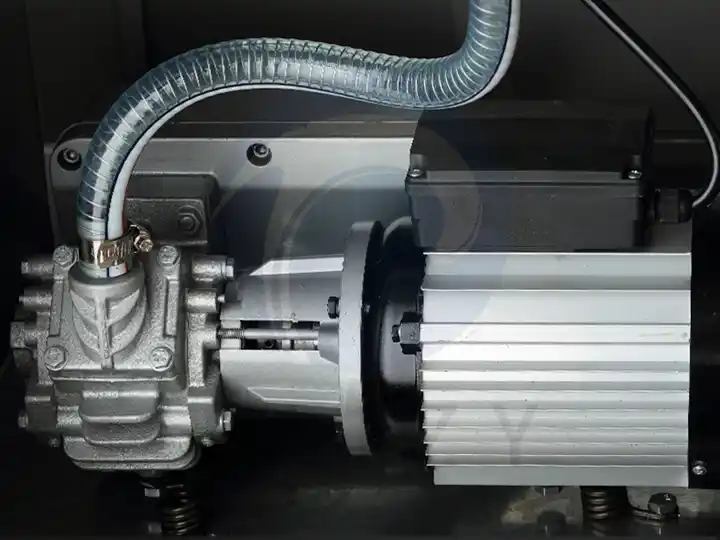

- Durable Vacuum Pump: Equipped with a high-power pure copper industrial pump for stronger vacuum, alloy heating wires for even heating and airtight sealing, and a pure copper transformer for long-lasting performance—machine lifespan can exceed 10 years.

- Efficient Sealing: High suction vacuum pump combined with wide and even sealing ensures tight and efficient seals.

- Low Noise: Runs quietly to protect operators’ hearing.

- Sturdy Machine Body: Thickened stainless steel body resists deformation and corrosion better than ordinary aluminum, and is easy to clean.

- High Packaging Efficiency: Can pack multiple bags at once or single bags as needed.

- Customizable: Voltage, plugs, machine chamber depth, and materials can be customized.

- Safer Power Supply: Thickened, aging-resistant power cords ensure safer electricity use.

- High-Quality Sealing Strips: Fast and even heating for tight, strong, and neat seals.

- Mobile with Swivel Casters: Durable rubber wheels rotate 360°, making it easy to move and relocate the machine; wheels can be upgraded if needed.

Technical Specifications of Fresh Corn Vacuum Pack Machines

Here are our standard models, with customization available. You are welcome to contact us at any time or request that we provide you with a vacuum packaging solution.

| Model | Power | Material | Pump | Lid material | Weight | Size(cm) | CBM |

| TZ-400A | 0.9kw | SS304 | 20L | Acrylic | 60Kg | 60*55*96 | 0.33 |

| TZ-400/2H | 0.9kw | SS304 | 20L | Acrylic | 65Kg | 60*55*50 | 0.34 |

| TZ-400/2S | 0.9kw | SS304 | 20L | Acrylic | 80Kg | 65*60*100 | 0.39 |

| TZ-500/2H | 0.9kw | SS304 | 20L | Acrylic | 80kg | 75*65*102 | 0.5 |

| TZ-600/2H | 1.5kw | SS304 | 20L/20*2 | Acrylic | 85Kg/100Kg | 85*75*102 | 0.65 |

Fresh Corn Vacuum Packing Process

Flowchart

Corn cob quality inspection → Husk and silk removal → Trimming, cleaning, grading → Blanching → Cooling → Vacuum packing → High-temperature sterilization → Cooling and packaging → Final packaging inspection → Storage → Finished product sales

Recommended Supporting Equipment

Blanching machine → Cooling machine → Vacuum packing machine → Sterilization kettle → Drying/wiping equipment → Inspection and storage

Processing Steps

Receiving and Selection

- Select fresh corn cobs harvested according to standards. Avoid throwing or squeezing during handling.

- Requirements: no insect damage, full kernels, natural color.

- Minor insect damage is allowed if the length meets standards after trimming.

Peeling and Silk Removal

- Gently remove husks and silk; discard moldy, watery, poorly developed, or immature corn.

Trimming, Cleaning, and Grading

- Manually cut off tips and bad kernels, ensuring clean cut surfaces.

- Quickly wash to remove impurities and silk; avoid long soaking.

- Grade by length into 4 categories: 12–14 cm, 14–16 cm, 16–18 cm, 18–20 cm.

Blanching

- Blanch in 95–100°C hot water for 10–12 minutes, adding 0.1% citric acid and 1% salt.

- Purpose: deactivate enzymes, sterilize, and preserve freshness. Hot water or steam can be used.

Cooling and Bagging

- Cool with cold water spray or soaking for 3–5 minutes, lowering surface temperature below 50°C.

- Keep bag openings clean during packing, avoid syrup or debris contamination.

Vacuum Sealing

- Vacuum pressure: 0.08–0.09 MPa. Vacuum for 12–20 seconds; heat seal for 3–5 seconds.

- Check seals for flatness and cleanliness. Fully automatic stretch film machines can improve efficiency.

High-Temperature Sterilization

- Sterilization parameters: 121°C, 15-20-20 (15 min preheating, 20 min holding, 20 min cooling).

- Use reverse pressure cooling to prevent bag bursting; cool to 40°C.

Wiping and Quality Inspection

- Wipe bags dry with a cloth to remove moisture and stains.

- Conduct a third quality check; discard unqualified products. For large batches, bag dryers can be used.

Storage and Observation

- Store finished products at 37°C for 7 days, turning twice during this period.

- Before shipment, inspect for swollen bags; qualified products are packed and stored for sale.

Wide Applications of Fresh Corn Vacuum Packing Machine

Agricultural Products

- Fresh corn and glutinous corn: Extend shelf life and prevent oxidation.

- Frozen vegetables like carrots, asparagus, and edamame: Vacuum packaging preserves freshness and color during freezing.

- Garlic, ginger, sweet potatoes, yams: Vacuum-packed for room temperature sales or refrigerated transport.

Meat and Seafood

- Fresh meats (e.g., beef steak, lamb chops): Prevent blood leakage, maintain texture and color.

- Pickled meats, sausages, cured meats: Prevent mold and moisture, ease transport and sales.

- Frozen seafood (shrimp, fish fillets, scallops): Vacuum-packed to avoid freezer burn.

Cooked and Ready-to-Eat Foods

- Cooked corn, boiled eggs, tofu products, rice, and ready meals: Combined with high-temperature sterilization for room temperature storage.

- Vacuum meal packs: Used in catering chains for standardized meal delivery.

Dry Food Products

- Nuts, dried fruits, tea leaves, mushrooms, and herbal medicines: Vacuum packaging protects against moisture, insects, and oxidation.

Non-Food Applications

- Pharmaceuticals: Vacuum packaging of medicines, herbs, and medical gauze to prevent moisture and contamination.

- Industrial Goods: Vacuum packaging metal parts and electronic components to prevent oxidation, rust, and static.

- Apparel and Home Textiles: Vacuum compression packaging for down jackets, bedding, to save space and facilitate e-commerce storage and shipping.

Shuliy Packaging Machine – Detailed Showcase

Parts List

Standard Configuration

| No. | Part Name |

| 1 | Vacuum Pump |

| 2 | Vacuum Chamber |

| 3 | Sealing Bar |

| 4 | Silicone Sealing Gasket |

| 5 | Control Panel |

| 6 | Power Cable & Plug |

| 7 | Safety Lid |

| 8 | Tool Kit |

| 9 | User Manual |

Wear Parts

| No. | Part Name |

| 1 | Heating Strip/Wire |

| 2 | Silicone Sealing Bar |

| 3 | Vacuum Pump Oil |

| 4 | Sealing Gaskets |

| 5 | Fuses |

Optional Accessories

| No. | Part Name |

| 1 | Gas Flushing System |

| 2 | Stainless Steel Stand |

| 3 | Extended Sealing Bar |

| 4 | Double Sealing Bars |

Spare Parts Recommendations

| Spare Part | Suggested Quantity |

| Heating Strips | 3–5 sets |

| Vacuum Pump Oil | 2–3 bottles |

| Fuses | Several |

| Sealing Gaskets | 2 sets |

Deep Processing of Corn

In addition, we also offer corn threshers and corn grits-making machines. Feel free to contact us for more information. We will provide you with the most cost-effective corn processing solution.