74 Units of 9FQ-320 Corn Hammer Mills Shipped to Morocco

In June 2025, a distributor from Morocco purchased 74 units of our 9FQ-320 corn hammer mills. The machines have now been fully delivered to the customer.

Customer Background

The customer is an agricultural machinery distributor based in Morocco, mainly supplying small grain processing machines to local farmers and feed factories. With the growing demand for livestock farming and feed processing in Morocco, the customer decided to expand their business and sought crushing equipment with stable performance, easy operation, and low maintenance costs.

Project Details

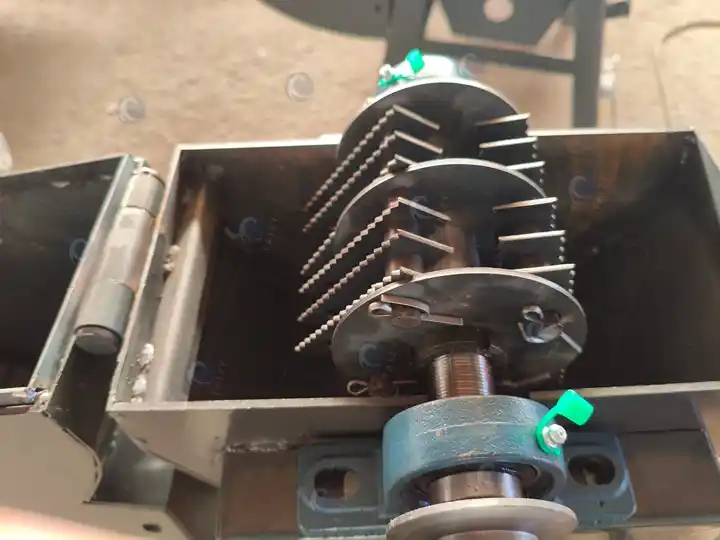

After thoroughly understanding the customer’s requirements, we recommended the 9FQ-320 small maize hammer mill. This model features a compact structure and small size, making it ideal for medium and small feed mills as well as family farms. The machine can not only crush grains such as corn, wheat, and soybeans but also process agricultural waste like corn stalks and peanut shells, achieving effective resource recycling.

After finalizing the solution, we customized the machines according to Morocco’s local voltage standards and usage habits. Each unit was equipped with a copper-core motor and a European standard plug, along with a protective belt cover to ensure compliance with European safety standards.

Recommended Equipment Details

- Model: 9FQ-320

- Quantity: 74 units

- Capacity: 100–200 kg/h

- Power: 2.2 kW

- Voltage: 220V

- Dimensions: 660×350×850 mm

- Weight: 70 kg

- Features: Copper-core motor, 2-meter protective drive belt cover, European standard plug

- Note: The motor is available in both aluminum-core and copper-core options. Since the customer required a more durable motor, the copper-core version was selected, which is slightly more expensive.

Shipping and After-Sales

All 74 corn hammer mills were shipped in a full container. Before loading, our sales staff personally inspected each machine to ensure there was no damage. The machines were packed in reinforced export wooden crates to guarantee their safety during transportation.

After the equipment arrived, we provided detailed operation manuals and instructional videos. We also assisted the customer online to complete equipment setup and user training.

Customer Feedback

“Taizy’s corn hammer mills are of excellent quality, easy to use, and perform reliably. Our clients are very satisfied.”

The customer also plans to continue cooperating with us and distribute more feed processing equipment.

Why Choose Taizy?

- Superior Performance: Made with high-strength steel and a copper-core motor for stable operation, low noise, and long service life.

- Wide Capacity Range: 100–3000 kg/h, suitable for households, small factories, and large feed mills.

- Versatile Power Options: Can be driven by an electric motor, a diesel engine, or a gasoline engine, with power ranging from 2.2 kW to 75 HP to suit different working environments.

- Flexible Grinding: Customizable screen diameters (2mm–10mm) allow production of powders or pellets of varying sizes.

- Compact Structure: Small footprint, easy installation, and simple maintenance, suitable for various production scenarios.

- Multi-Purpose: Can crush grains such as corn, wheat, and soybeans, as well as agricultural residues like straw, peanut shells, rice husks, and sawdust.

- Reliable Quality: All equipment is CE and ISO9001 certified and manufactured strictly according to European standards.

- Professional Manufacturer: Taizy Machinery has over 20 years of experience in agricultural processing equipment manufacturing, with products exported to more than 100 countries.

What Taizy Can Offer

- One-on-One Selection Advice – Personalized guidance to choose the right equipment for your needs.

- Customized Solutions – Tailored equipment and solutions based on your production requirements.

- Fast Delivery & Remote Installation Support – Quick shipping with online guidance for setup and operation.

- 1-Year Warranty & Lifetime Technical Support – Ensuring long-term reliability and assistance.