How to Use Fully Automatic Corn Flour Packaging Machine?

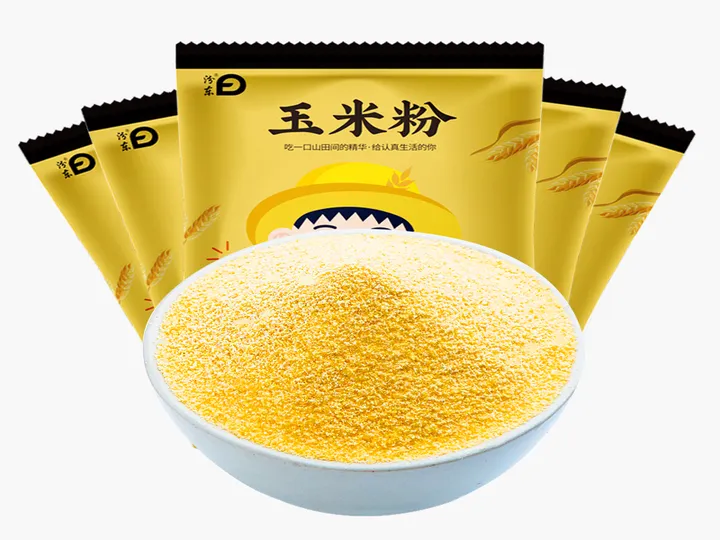

The 3 kg fully automatic corn flour packaging machine is widely used for the quantitative packaging of powders such as corn flour, wheat flour, milk powder, and cassava powder. This machine integrates bag making, weighing, filling, sealing, and coding, significantly improving packaging efficiency while ensuring quality.

This article will focus on the detailed working process, correct usage, and key features of the corn flour packaging machine to help users better understand and operate the equipment.

Detailed Working Process of the Corn Flour Packaging Machine

The 3 kg fully automatic corn flour packaging machine uses a vertical packaging structure and is controlled by a PLC program, achieving continuous and stable automatic packaging. The complete working process is as follows:

- Film Unwinding and Forming

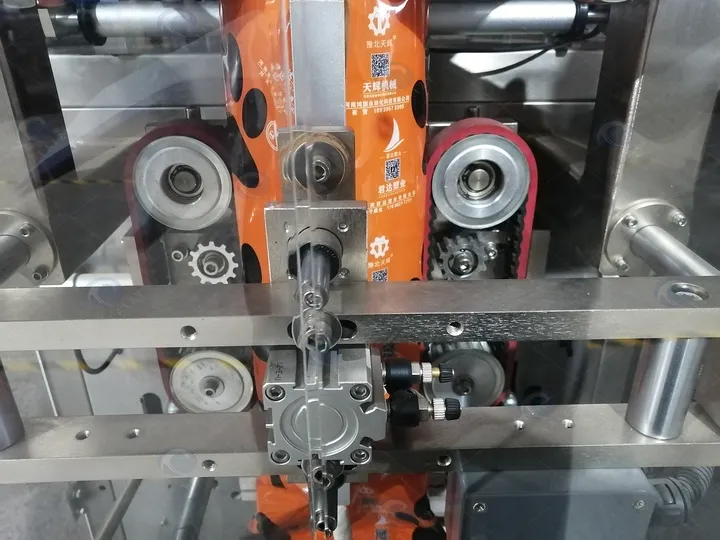

The packaging film enters the machine from an external roll holder and moves forward smoothly under the drive of the dual servo belt system. The former folds the flat film into a tubular shape, preparing the bag for filling. - Automatic Bag Making and Positioning

The machine uses the pre-set bag length and width from the touch screen. The servo precision positioning system automatically controls the bag size, ensuring each bag is uniform with minimal error. - Screw Feeding and Filling

Corn flour is quantitatively delivered through the screw feeding system. The powder is evenly pushed into the formed bags. The filling process is stable and precise, effectively preventing weight errors caused by poor powder flow. - Sealing and Shaping

After filling, the machine seals the bag mouth with heat. The screw feeding structure prevents powder from interfering with the seal, ensuring a neat, firm, and aesthetically pleasing seal, improving packaging quality. - Coding and Bag Cutting

The machine can automatically print production dates, batch numbers, and other information on the bag as needed. It then cuts the bag precisely, and the finished bags are automatically discharged for subsequent boxing or stacking.

The entire process runs continuously, reduces manual intervention, and is suitable for long-term stable operation.

How to Properly Use the Corn Flour Packing Machine?

To ensure stable operation and extend the machine’s lifespan, follow these steps:

Pre-Startup Check

- Confirm that the power voltage (220V or 380V) matches the machine’s requirements.

- Check that the air pressure is stable around 0.65 MPa.

- Ensure sufficient packaging film and corn flour are prepared.

Parameter Setting

- Use the color touch screen to set:

- Packaging weight (3 kg or other preset value)

- Bag length and width

- Packaging speed

- After setting, run an empty test or a small batch to ensure normal operation.

Normal Operation

- Once started, the machine will automatically make bags, weigh, fill, and seal.

- Operators only need to monitor the process and replenish material or packaging film as needed.

During Operation

- Avoid hard impurities in the raw material to prevent damage to the screw feeding system.

- Regularly check sealing quality and packaging weight to ensure finished product standards.

- Stop the machine immediately if an alarm occurs and inspect the issue.

Daily Cleaning and Maintenance

- After production, clean the feeder, sealing area, and machine surface of any powder residue.

- Keeping the machine clean helps maintain stable long-term operation and meets food hygiene requirements.

Key Features of the Corn Flour Packaging Machine

Highly Automated, Multi-Functional

Integrates bag making, weighing, filling, sealing, coding, and cutting into one machine, reducing manual labor and improving production efficiency.

Screw Feeding, Accurate Measurement

The screw metering system is specially designed for powders, ensuring stable filling, minimal weight error, and cleaner seals.

Servo Control, Stable Bag Size

Dual-belt servo traction with precision positioning ensures smooth film feeding, attractive bag shape, and consistent specifications.

Fully Enclosed, Dust-Proof Structure

Effectively prevents powder from entering the machine, suitable for long-term continuous production of food-grade powders.

Flexible Voltage and Standards

Supports 220V/380V power supply, with plug options customizable for different countries, making it suitable for export.

Easy Film Replacement

The external roll holder design allows quick film changes. Bag misalignment can be adjusted with one touch on the screen, making maintenance and upkeep more time- and labor-efficient.

Main Technical Parameters of the 3 kg Corn Flour Packaging Machine

| Item | TH-420 | TH-520 | TH-720 |

|---|---|---|---|

| Type | TH-420 | TH-520 | TH-720 |

| Bag Length | 80–300 mm | 80–400 mm | 100–400 mm |

| Bag Width | 50–200 mm | 80–250 mm | 180–350 mm |

| Max Film Width | 420 mm | 520 mm | 720 mm |

| Packing Speed | 5–30 bags/min | 5–50 bags/min | 5–50 bags/min |

| Measuring Range | 5–1000 ml | Max 3000 ml | Max 6000 ml |

| Air Pressure | 0.65 MPa | 0.65 MPa | 0.65 MPa |

| Gas Consumption | 0.3 m³/min | 0.4 m³/min | 0.4 m³/min |

| Power Voltage | 220 V | 220 VAC / 50 Hz | 220 VAC / 50 Hz |

| Power | 2.2 kW | 4.4 kW | 5 kW |

| Machine Size (L×W×H) | 1320 × 950 × 1360 mm | 1150 × 1795 × 1650 mm | 1780 × 1350 × 1950 mm |

| Machine Weight | 540 kg | 600 kg | 720 kg |

Contact Us

Taizy offers a full range of corn processing machines. In addition to the corn flour packing machine, we also provide corn grits machines, corn hammer mills, and more. You are welcome to contact us for inquiries.