Fresh Corn Vacuum Pack Machine: Single Chamber vs. Double Chamber — Which One is Right for You?

As consumers demand better freshness for agricultural products, the need for vacuum packing fresh corn is rapidly growing. Fresh corn vacuum packaging machine not only helps extend shelf life but also makes transportation and sales more convenient.

Among the many vacuum pack machines available, single-chamber and double-chamber models stand out for their efficiency and practicality. But what are the key differences between them? And which one is better suited to your processing needs?

Single Chamber Vacuum Pack Machine – A Practical and Budget-Friendly Starter Option

The small commercial single-chamber vacuum packing machine is ideal for small to medium-sized fresh corn processors or newly established agricultural businesses.

How It Works

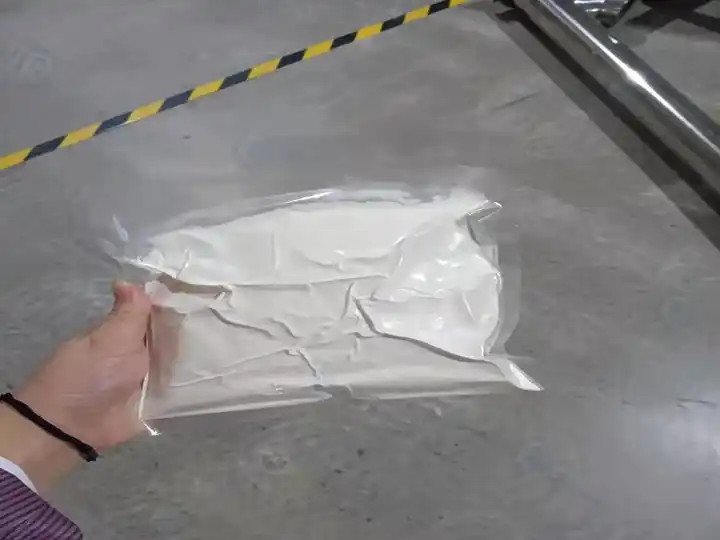

After placing fresh corn into a bag, it’s put inside the vacuum chamber. The machine automatically removes the air from the bag and heat-seals it. Once the process is finished, the vacuum lid opens, and the packaged product is ready to be taken out.

Key Features

- Compact design, small footprint: Ideal for production spaces with limited room.

- Easy to operate: Just set the vacuum and sealing time, then press a button to start.

- High cost performance: Low investment cost, perfect for startups or small-batch production.

- Easy maintenance: Fewer parts make it simple to maintain and repair.

- Flexible packaging options: Supports vacuum packing of single or multiple ears of fresh corn.

Recommended: Multifunctional Industrial Single Chamber Vacuum Pack Machine for Fresh Corn

Advantages of the Equipment

- 20L Industrial Vacuum Pump: Ensures fast and thorough air removal with a vacuum rate of up to 20 m³/h.

- Reinforced Stainless Steel Body: All food-contact parts are made of 201 stainless steel; non-contact parts use SUS304 for durability, resistance to deformation, and easy cleaning.

- Enlarged Inner Chamber: The upgraded dome lid withstands higher pressure and is made from transparent organic material for easy observation during vacuuming.

- Integrated Heat Dissipation Vents: Keeps the machine cool for long working hours without damage.

- Wide Application Range: Suitable for vacuum packing fresh corn, as well as dry, wet, oily, and powder products — all-in-one functionality.

- Multiple Model Options: A variety of machine types and sizes are available to meet different production needs and fit various workspace sizes.

- High Productivity: Capable of sealing thousands of packs per day; supports 24-hour continuous operation.

- Smarter Controls: Equipped with an intelligent control panel that’s easy to use and features a memory function for added convenience.

- Tight Sealing: 10mm wide effective sealing ensures no leakage, even with oil or moisture in the bag.

- Bag Compatible: Works with various bag types, including vacuum foil bags, nylon bags, folded edge vacuum bags, textured bags, and mixed-material bags.

- Quality Guarantee: We offer a 12-month warranty, so you don’t have to worry about after-sales service.

Recommended Product Specifications

Model:TZ-500/2H

Power:0.9kw

Material: SS304

Vacuum pump size: 20L

Lid material: Acrylic

Weight: 80kg

Size(mm): 750*650*1020

CBM: 0.5

The above model is just one of the many options we offer. We provide a wide range of machine models and sizes to meet different production needs. If you’d like to learn more about available models and specifications, please feel free to contact us.

Double Chamber Vacuum Pack Machine: A High-Efficiency, Reliable Production Unit

The double-chamber vacuum pack machine is an ideal choice for medium to large-scale fresh corn processing plants. It is especially suitable for operations that require high output and long hours of continuous work.

How It Works

The double chamber vacuum pack machine features two vacuum chambers. While Chamber A is vacuuming and sealing the bags, Chamber B can be used to prepare the next batch. The two chambers work alternately, significantly boosting overall efficiency.

Key Features of the Double Chamber Vacuum Pack Machine

- Alternating Dual Chambers: While one chamber is vacuuming, the other can be loaded — greatly improving work efficiency.

- Longer Sealing Length: Allows multiple bags to be sealed at once, ideal for bulk orders.

- Durable Construction: Mostly made of stainless steel, corrosion-resistant and easy to clean.

- Optional Auto Lid Lift: Some models support automatic lid flipping to reduce manual effort and increase automation.

- Suitable for Continuous Operation: Designed to handle large-volume fresh corn packaging needs.

- High Output Capacity: Capable of packing multiple bags at once, improving productivity.

Recommended Product Specifications

Model:TZ-500/2SD

Power:1.5kw

Material: SS304

Vacuum pump size: 20L *2

Lid material: Acrylic

Weight: 150kg

Size(mm): 1300*780*1000

CBM: 1.2

How to Choose the Right Fresh Corn Vacuum Pack Machine?

Select Machine Type Based on Production Volume

- For small-batch production or trial runs: A single-chamber vacuum pack machine is recommended. It has a simple structure, is easy to operate, and is more affordable.

- For medium to large-scale packaging: A double chamber vacuum pack machine is preferred for higher efficiency and labor savings, especially suitable for continuous operation and export-oriented businesses.

Match Machine Size to Corn Shape

- If the corn ears are long, choose models with a wider or deeper vacuum chamber. Both single and double chamber machines can be customized with enlarged chambers.

Check the Vacuum Pump Configuration

- The vacuum pump is the core component. High-power oil pumps provide stronger vacuum and tighter seals, effectively extending the freshness of corn.

- Brand-name pumps (like Germany’s BUSCH) offer more stable quality but come at a higher price.

Material and Build Quality for Hygiene and Safety

- It’s best to select machines made entirely of 304 stainless steel for their exceptional corrosion resistance, ease of cleaning, and compliance with food safety standards.

- Sealing bars should be high-temperature resistant, and internal wiring should be neat and waterproof.

Ease of Operation and Maintenance

- Modern machines feature touch control panels, automatic lid lifting, and adjustable sealing times and temperatures—these add convenience.

- Choose manufacturers who provide good after-sales service, spare parts availability, and technical support, especially important for seasonal fresh corn processors.

Budget and Brand

- Single chamber machines are generally much cheaper than double chamber ones; prices vary based on configuration.

- Opt for experienced, professional suppliers to ensure quality, timely delivery, and reliable technical support.

If you are a food factory, agricultural cooperative, cooperative farmer, or exporter, it’s recommended to prioritize high-efficiency, durable, and easy-to-operate double-chamber machines. However, if you are a beginner trying out vacuum packaging or handling small-scale packaging and sales, an economical single-chamber machine can also meet your daily needs.