Molino de martillos de maíz para moler maíz, arroz y trigo

| Modelo | Serie 9FQ |

| Capacidad (kg/h) | 100-3000 |

| Potencia (kilovatios) | 2.2-55 |

| DIa del tamiz (mm) | 0.5-5 |

| Martillo (uds) | 16/24/32/40/64 |

| Peso (kg) | 50-1200 |

| Tamaño (mm) | Según la tabla |

| Garantía | 12 meses |

Ahora puede solicitar detalles técnicos a nuestros jefes de proyecto

La máquina molino de maíz es una máquina de molienda multifuncional. Puede triturar eficientemente granos como maíz, trigo y soja, así como procesar materiales como paja de trigo, tallos de maíz y cáscaras de cacahuete en polvo fino o pellet. Es una opción ideal para la producción de alimentos y el reciclaje de residuos agrícolas.

Según diferentes modelos, las máquinas de molino de martillos de maíz Taizy tienen una capacidad que va desde 100–3000 kg/h, satisfaciendo las necesidades de la mayoría de las empresas.

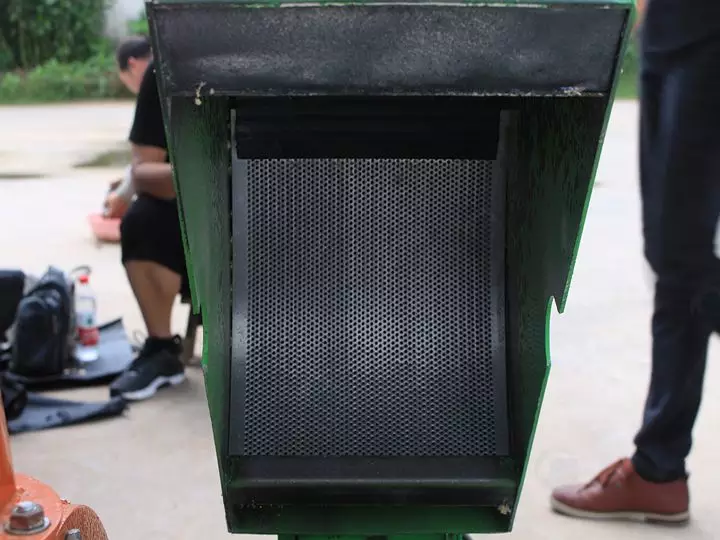

Esta máquina molino de martillos tiene un amplio rango de aplicaciones y puede producir materiales con diferentes tamaños de partícula.La finura del polvo depende principalmente del tamaño de los agujeros de la malla. Podemos personalizar mallas con diferentes aberturas según tus materias primas para asegurar que el producto final satisfaga tus necesidades de producción. Los tamaños de malla comunes incluyen 2 mm, 3 mm, 4 mm, 5 mm, 8 mm y 10 mm.

Nuestra molino de maíz puede ser alimentado por un motor diésel, motor de gasolina o motor eléctrico, lo que lo hace adecuado para diversas condiciones de trabajo. El motor puede alcanzar hasta 75 HP, proporcionando alta potencia y alta eficiencia.

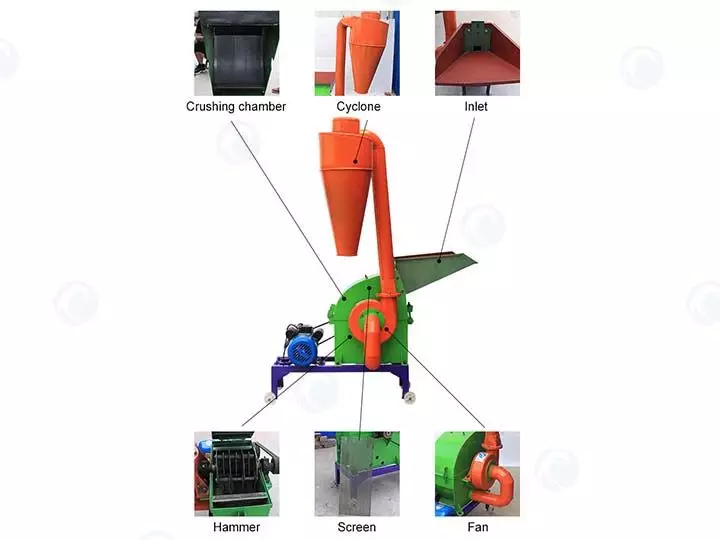

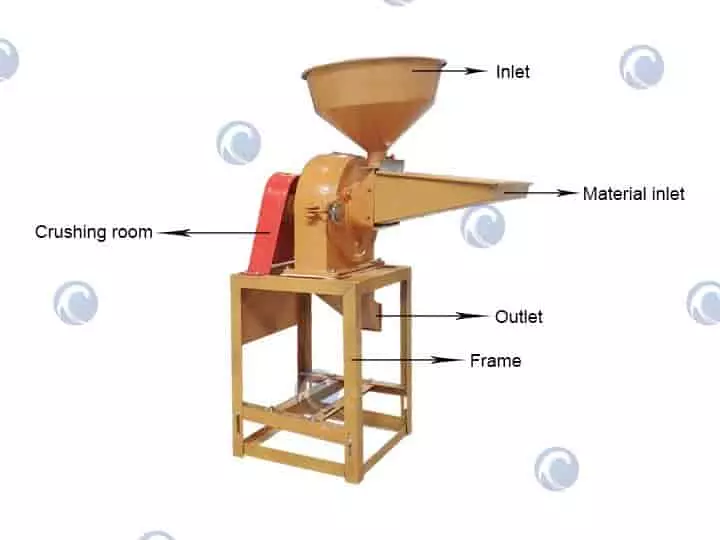

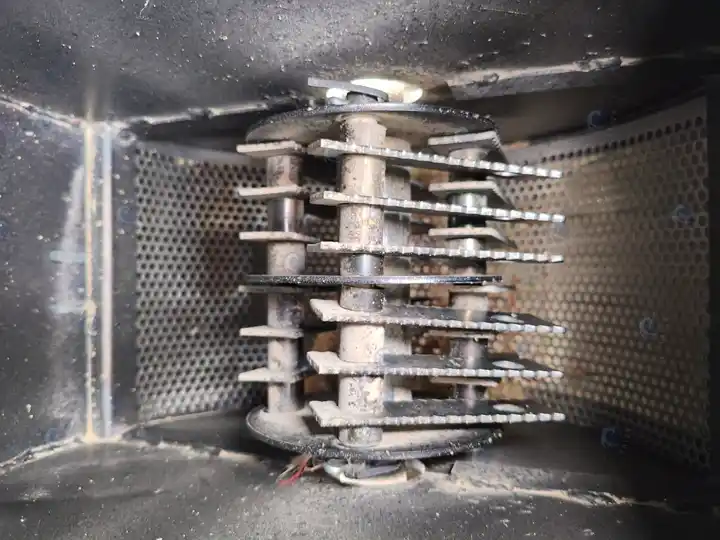

Diseño de molino de martillos para maíz.

La estructura del molino de martillos para harina de maíz comprende una cámara de trituración, una cámara de alimentación, una cámara de separación ciclónica, un rotor y una base.

Cámara de alimentación

- Función: Alimenta de manera uniforme materias primas como maíz, granos y paja en la cámara de trituración.

- Características: Equipado con un dispositivo de prevención de retroceso para evitar la fuga de polvo; puede combinarse con un alimentador automático para una alimentación continua.

Cámara de trituración

- Función: La parte principal de trabajo de la máquina, donde las materias primas se trituran en polvo o pellets mediante impacto de martillo a alta velocidad, corte y fricción.

- Componentes: Incluye martillos, rotor, pantalla y revestimiento.

- Características: Aberturas de pantalla reemplazables para controlar la finura del polvo.

Rotor

- Función: Impulsa los martillos a girar a alta velocidad para triturar el material.

- Características: Bien equilibrado, de alta velocidad (generalmente más de 2800 RPM), que afecta directamente a la eficiencia de trituración y la uniformidad de las partículas.

Ciclón Separador

- Función: Separa el polvo triturado del aire para garantizar una recolección suave y reducir la sobrecarga de polvo.

- Características: Utiliza fuerza centrífuga para la separación; estructura sencilla con eliminación efectiva del polvo.

¿Cuáles son los parámetros de la máquina?

| Modelo | Capacidad (kg/h) | Martillo (piezas) | Potencia (kilovatios) | Potencia(Hp) | Diámetro del tamiz (mm) | Peso (kg) | Tamaño (mm) |

| 9FQ-320 | 100 | 16 | 2.2 | 5 | 0.5-5 | 50 | 1200*500*1000 |

| 9FQ-360 | 150 | 24 | 5.5 | 8 | 0.5-5 | 120 | 1100*600*1200 |

| 9FQ-420 | 200 | 24 | 11 | 15 | 1.2-3 | 200 | 1200*800*1900 |

| 9FQ-500 | 300 | 24 | 11 | 20 | 1.2-3 | 300 | 1200*800*1300 |

| 9FQ-600 | 500 | 32 | 18.5-22 | 30 | 1.2-3 | 500 | 1500*900*1500 |

| 9FQ-750 | 850 | 32 | 22-30 | 35 | 1.2-3 | 850 | 1500*1000*1600 |

| 9FQ-800 | 1000 | 40 | 37 | 45 | 1.2-3 | 1000 | 2000*1300*1600 |

| 9FQ-1000 | 1200 | 64 | 45- | 75 | 1.2-3 | 1200 | 1500*1300*1800 |

A continuación se muestran los parámetros de 8 modelos populares de molino de maíz. El molino de maíz pequeño tiene una capacidad de 100 kg/h, mientras que la máquina de harina de maíz grande puede alcanzar 1200 kg/h. Si está interesado, no dude en contactarnos. También tenemos la máquina de molienda de granos de maíz y la máquina de molino de maíz de disco para la venta.

¿Cómo funciona el molino de martillos para maíz?

El modo de funcionamiento del molino harinero de maíz es muy sencillo. Primero, el operador enciende la fuente de alimentación y envía el material al puerto de alimentación. Luego, el material ingresará automáticamente a la cámara de molienda para su molienda. El martillo de alta velocidad en la cámara de trituración triturará rápidamente el maíz hasta convertirlo en polvo o gránulos. El producto final se descargará desde la salida a través de la pantalla.

Ventajas del molino de martillos para molienda de maíz

- Amplia gama de capacidades: Con una capacidad de 100 kg/h a 1200 kg/h, cumple con las necesidades de producción pequeña a mediana-grande.

- Potente y eficiente: : Puede ser alimentada por un motor diésel, gasolina o eléctrico, asegurando una trituración eficiente y un rendimiento estable.

- Materiales y estructura duraderos: El cuerpo está hecho de acero de alta calidad, resistente a la corrosión y robusto; el rotor, los martillos y los revestimientos están hechos de materiales de aleación resistentes al desgaste para una vida útil prolongada.

- Tamaño de partícula ajustable: Equipado con pantallas reemplazables con aberturas de 2 a 12 mm, permitiendo un control preciso de la finura del polvo para cumplir con diferentes requisitos de producción.

- Amplia aplicación: Puede triturar maíz, trigo, soja, paja, cáscaras de cacahuete y otros cultivos o residuos agrícolas en polvo fino o pellets, ideales para la producción de pienso y el reciclaje de residuos agrícolas.

- Diseño compacto y práctico: Los tamaños de la máquina varían desde 1200×500×100 mm hasta 2000×1300×1600 mm, con una estructura compacta para facilitar la instalación y el mantenimiento.

- Rotor de alto rendimiento: Rotor bien equilibrado con velocidades superiores a 2800 RPM que garantiza un tamaño de partícula uniforme y una trituración eficiente.

- Control eficiente del polvo: Equipado con un separador ciclónico para separar eficazmente el polvo del aire, reduciendo la fuga de polvo y manteniendo limpio el entorno de trabajo.

¿Cómo utilizar correctamente el molino de martillos de maíz?

- Antes de arrancar la máquina, verifique si cada parte de la máquina presenta anomalías evidentes y si los tornillos están flojos.

- La máquina debe funcionar en seco durante varios minutos al arrancar. Escuche sonidos anómalos y una correa suelta.

- El usuario no debe meter la mano en la máquina durante la alimentación.

- Una bolsa debe estar conectada en la salida para recoger los productos terminados. Esto puede evitar la situación en que los materiales en polvo no se recolectan fácilmente.

- Revise los cojinetes y reemplace el aceite lubricante cuando la máquina funcione durante 500 horas.

- Después de la operación de la máquina molino de maíz, la entrada de alimentación debe cerrarse y los restos deben limpiarse.

¿Cómo elegir la máquina adecuada de molino de maíz con martillos?

Elegir por capacidad

| Capacidad (kg/h) | Modelo adecuado | Notas |

|---|---|---|

| 100–150 | 9FQ-320 / 9FQ-360 | Producción a pequeña escala o uso doméstico/agrícola |

| 200–300 | 9FQ-420 / 9FQ-500 | Molinos de alimentación de pequeño a mediano tamaño o procesamiento de maíz pequeño |

| 500–850 | 9FQ-600 / 9FQ-750 | Empresas medianas, alta eficiencia |

| 1000–1200 | 9FQ-800 / 9FQ-1000 | Procesamiento de maíz a gran escala o producción industrial |

Consejo: Elige un modelo ligeramente por encima de tus necesidades reales (10–20%) para manejar picos de producción y evitar sobrecarga.

Considerar cantidad de martillos y potencia

- Más martillos → mayor eficiencia de trituración, partículas más finas y uniformes.

- Potencia adecuada → garantiza un funcionamiento estable; demasiado baja provoca sobrecarga del motor, demasiado alta desperdicia energía.

| Potencia (kW) | Capacidad recomendada | Características |

|---|---|---|

| 2.2–5 | 100–150 kg/h | Hogar o pequeñas molineras de alimento |

| 11–22 | 200–850 kg/h | Producción de tamaño medio, adecuada para operación continua |

| 37–45 | 1000–1200 kg/h | Operación industrial de alta capacidad, de uso pesado |

Consejo: Combina el número de martillos y la potencia con la capacidad requerida.

Considerar el diámetro de la malla para el tamaño de partícula

- Pantallas pequeñas (0.5–1.5 mm) → polvo más fino, adecuado para harina, alimento o uso industrial.

- Pantallas más grandes (2–5 mm) → partículas gruesas, adecuadas para alimento o grano de maíz.

Elegir según el uso downstream: alimento, harina de maíz o polvo de maíz.

Considere el tamaño de la máquina y el espacio de la sala de máquinas

- Modelos pequeños (9FQ-320 / 360) → ocupan menos espacio, aptos para talleres con espacio limitado.

- Modelos grandes (9FQ-800 / 1000) → ocupan más espacio, pueden requerir transportadores o tolvas.

Resumen del proceso de selección

- Determine la capacidad por hora/día → haga una selección de modelos adecuados.

- Considerar características del material (dureza, humedad, uso) → elegir potencia y tamaño de malla.

- Comprobar el espacio de taller → asegurar que la máquina se ajuste.

- Evaluar presupuesto → modelos pequeños son más baratos, los grandes son más productivos pero ocupan más espacio.

- Plan para expansión futura → seleccione una máquina ligeramente superior a la capacidad actual.

Ejemplo

- Molino de pienso pequeño, ~200 kg/h → elegir 9FQ-420, 11 kW, 24 martillos, malla 1.2–3 mm, coste-efectivo y fácil de mantener.

- Procesamiento industrial de maíz, >1000 kg/h → elegir 9FQ-800 o 9FQ-1000, alta potencia, más martillos, producción de alta capacidad estable.

Caso de éxito

Máquina molino de maíz con martillos vendida a Marruecos Distribuidor

- Cliente: Un distribuidor de Marruecos

- Modelo de máquina: Molino de maíz 9FQ-320

- Cantidad: 74 juegos

- Capacidad: 100–200 kg/h

- Dimensiones: 660×350×850 mm

- Potencia: 2,2kW

- Voltaje: 220V

- Peso: 70 kg

- Características: Equipada con motor de núcleo de cobre, cubierta de correa de 2 m y enchufe de norma europea.

Detalles

- El distribuidor marroquí compró 74 juegos de molinos pequeños para ampliar su red de producción de alimentación local.

- Se eligió el modelo 9FQ-320 por su estructura compacta, rendimiento estable y operación fácil, ideal para granjas pequeñas y talleres de alimentación.

- Cada máquina está equipada con motor de núcleo de cobre y una tapa de correa de seguridad, asegurando un funcionamiento eficiente y seguro.

- Nuestro equipo proporcionó guía profesional de instalación y operación para ayudar al cliente a empezar la producción rápidamente.

Si está interesado en nuestro molino de martillos para maíz, deje su información de contacto y requisitos en el formulario emergente a la derecha. Nos pondremos en contacto con usted en 24 horas para proporcionar más detalles y una cotización.