Fraiseuse de gruau de maïs | Machine à gruau de maïs

| Modèle | T3 |

| Pouvoir | 7,5 kW + 4 kW |

| Capacité | 300-400kg/heure |

| Taille | 1400*2300*1300mm |

| Poids | 680 kg |

| Date de production | 7-15 jours ouvrables |

| Période de garantie | 12 mois |

Vous pouvez désormais demander des détails techniques à nos chefs de projets

Le broyage du gruau de maïs Taizy peut produire à la fois du gros gruau de maïs, du petit gruau de maïs et de la farine de maïs. Le gruau de maïs fabriqué par cette machine a une couleur vive et propre et est de haute qualité.

En fonction de la capacité et de la configuration, Shuliy propose cinq modèles de machines de mouture de semoule de maïs : T1, T2, T3, C2 et PH.

Le modèle le plus vendu T1 peut traiter 1 000 kg de semoule de maïs par heure, avec 350–450 kg d'épluchage de maïs et 350 kg de farine de maïs. Le modèle T3 produit 300–400 kg par heure. Nous recommandons les modèles T1 et T3 comme options les plus populaires.

Et le gruau de maïs peut être vendu directement dans les supermarchés et sur les marchés de gros de céréales/huile. Cette machine a donc un large éventail d’applications.

Les avantages de la machine de fabrication de gruau de maïs Taizy

- Vous pouvez obtenir trois produits à base de maïs en même temps. Avec l'aide de notre fraiseuse à gruau de maïs, vous pouvez obtenir du petit gruau de maïs, du gros gruau de maïs et de la farine de maïs.

- Le haut degré d'automatisation. La machine de fabrication de gruau de maïs termine le processus de nettoyage, d'épluchage, de désembryage, de déracinement, de concassage, de broyage, de classement et de polissage du gruau de maïs en une seule fois.

- Le produit fini est propre. Le modèle T3 est équipé d'une unité d'extraction de poussière, et les grits de maïs produits peuvent être vendus directement en supermarché.

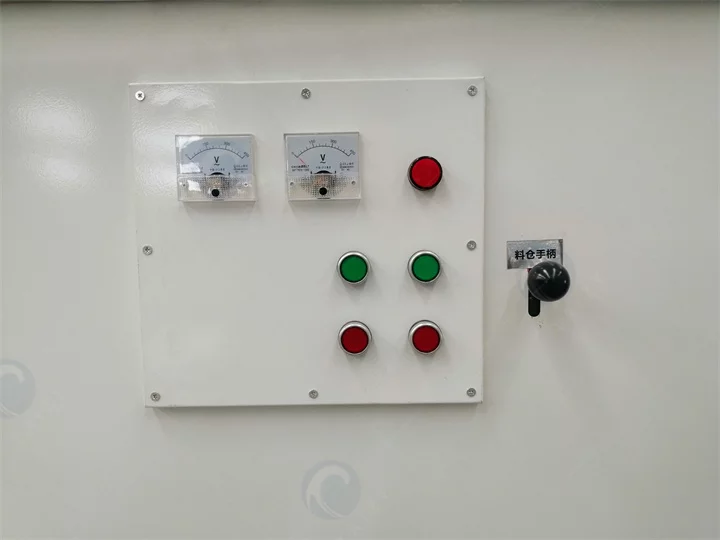

- Facile à utiliser. Panneau de commande à bouton-poussoir, facile à apprendre.

- Plusieurs modèles. Nous avons 5 types de machines différents à vendre. Il peut répondre à un large éventail de besoins des clients.

Quels sont les types de fraiseuses à maïs ?

En tant que fabricant professionnel d'équipements de transformation du maïs, nous avons 5 types de machines à moudre le gruau de maïs à vendre. Il s'agit respectivement des T1, T3, PH, PD2 et C2.

Ces cinq machines présentent des caractéristiques et des avantages différents. Ensuite, je vais vous présenter ces cinq machines en détail. Les clients peuvent choisir en fonction de leurs besoins.

Type 1 : T1 petite machine de mouture de semoule de maïs

Caractéristiques

- Options d'alimentation: Moteur électrique ou moteur diesel

- Capacité : Pelage du maïs 350–450 kg/h; grits de maïs 1000 kg/h; farine de maïs 350 kg/h

- Vitesse de l'arbre principal : 1150 rpm

- Configuration: Machine unique; doit être pelée avant de moudre; ne peut pas peler et faire des grits simultanément

- Matériau/Structure : Corps en acier au carbone standard; facile à utiliser

- Convient pour : Petites exploitations agricoles et petites usines de traitement des grains

T1 Petite machine de mouture de semoule de maïs – paramètres techniques

| Modèle | T1 |

| Épluchage de maïs | 200kg/h |

| Faire du gruau de maïs | 1000kg/heure |

| Faire de la farine de maïs | 350kg/h |

| Tension nominale | 380v |

| Pouvoir | 7,5 kW |

| Vitesse de broche | 1150 tr/min |

Type 2 : grande machine à semoule de maïs T3

Caractéristiques

- Options d'alimentation : Moteurs doubles (7,5 kW 4 kW)

- Capacité : 300–400 kg/h

- Dimensions : 1400 × 2300 × 1300 mm

- Poids : 680 kg

- Configuration: Peut peler et faire des grits en même temps; équipé d'un séparateur cyclone pour les cosses de maïs et la poussière

- Matériau/Structure : Corps en acier au carbone; fonctionnement efficace

- Convient pour : Usines de traitement de capacité moyenne avec des exigences élevées de propreté du produit

Grande machine à semoule de maïs T3 – paramètres techniques

| Modèle | T3 |

| Pouvoir | 7,5 kW + 4 kW |

| Capacité | 300-400kg/heure |

| Taille | 1400*2300*1300mm |

| Poids | 680 kg |

Type 3 : machine à semoule de maïs PD2

Caractéristiques

- Options d'alimentation : Moteur de 15 kW

- Capacité : 400 kg/h

- Dimensions : 265 × 125 × 320 cm

- Configuration: Système entièrement automatique avec deux élévateurs machine à pelure et à grits; peut inclure un nettoyeur, un convoyeur à vis, et un silo à grains

- Matériau/Structure : Corps en acier entièrement en acier; durable et fiable

- Convient pour : Usines de traitement de moyenne à grande capacité avec des besoins de production élevés; peut former une petite ligne de production de grits de maïs

PD2 machine de mouture de semoule de maïs – paramètres techniques

| Modèle | PD2 |

| Pouvoir | 15kw |

| Capacité | 400kg/h |

| Taille | 265*125*320cm |

Type 4 : machine à semoule de maïs PH

Caractéristiques

- Options d'alimentation : Moteur de 11 kW

- Capacité : 300 kg/h

- Dimensions : 200 × 130 × 65 cm

- Configuration: Similaire au T3 mais sans système d'extraction de poussière

- Matériau/Structure : Compact, durable, facile à utiliser

- Convient pour : Clients soucieux du budget ou ayant des exigences modérées de propreté du produit

Machine à semoule de maïs PH – paramètres techniques

| Modèle | PH |

| Capacité | 300kg/h |

| Pouvoir | 11kw |

| Taille | 200*130*65cm |

Type 5 : machine C2 de fabrication de semoule de maïs

Caractéristiques

- Options d'alimentation : Moteur (puissance similaire à PH)

- Capacité : ~300 kg/h (similaire à PH)

- Dimensions/Poids : Semblable à PH

- Configuration: Version simplifiée pour les clients économiques

- Matériau/Structure : Corps en acier au carbone standard

- Convient pour : Petites exploitations agricoles ou usines de traitement des grains à budget limité

Comparaison de cinq modèles de machines à semoule de maïs

Similitudes

- Tous peuvent transformer le maïs en grosses semoules, petites semoules et farine de maïs.

- Les composants de base sont similaires : trémie, système d'épluchage, système de broyage et sortie.

- Convient aux petites et moyennes usines de traitement des grains, et relativement facile à utiliser.

- Options d'alimentation : moteur électrique ou moteur diesel (certains modèles ont des doubles moteurs ou une configuration moteur fixe).

Différences

- T1 : Machine unique ; doit éplucher avant de moudre ; capacité modérée ; options d'alimentation flexibles.

- T3 : conception à double moteur ; peut éplucher et moudre en même temps ; équipé d'un séparateur cyclone pour des produits plus propres ; haute efficacité.

- PH : Similaire au T3 mais sans élimination de la poussière ; prix plus bas ; compact ; efficace.

- C2 : Semblable à PH en fonction et apparence ; prix plus bas ; adapté aux clients soucieux de leur budget.

- PD2 : Équipé de doubles élévateurs et d'un nettoyeur ; entièrement automatique ; grande capacité avec sortie propre ; peut former une petite ligne de production pour des besoins à haut rendement.

Tableau comparatif concis des modèles de machines à moudre la semoule de maïs

| Modèle | Puissance (kW) | Capacité (kg/h) | Caractéristiques spéciales | Prix / Adéquation |

|---|---|---|---|---|

| T1 | 7.5 | Épluchage 350 Semoule 1000 Farine 350 | Machine unique alimentation manuelle | Moyen |

| T3 | 7.5 + 4 | 300–400 | Séparateur cyclone | Moyen–Élevé |

| PH | 11 | 300 | Pas d'élimination de la poussière | Faible |

| C2 | Semblable à PH | Semblable à PH | Fonctions simplifiées | Faible |

| PD2 | 15 | 400 | Plus propre et doubles élévateurs | Élevé |

Guide d'achat

- Pour une haute efficacité et une sortie propre → choisissez T3 ou PD2.

- Pour un budget limité → choisissez PH ou C2.

- Pour une exploitation flexible et un traitement étape par étape → choisissez T1.

Quel est le procédé de fabrication du gruau de maïs ?

Après avoir découvert les 5 différents types de machines de fabrication de gruau de maïs, souhaitez-vous savoir comment fonctionnent ces machines ? Ensuite, je vais vous présenter en détail.

- Tout d’abord, nous devons verser le maïs de la trémie dans la salle d’épluchage de la machine à gruau de maïs. Le maïs est poussé vers la chambre d'épluchage par le hélicela rotation.

- Dans la chambre de pelage, la densité entre les cors va augmenter en raison de la réduction progressive du volume de la chambre de travail et de l'influence de la résistance mécanique.

- L'enveloppe du maïs se détachera en raison du serrage et du frottement à l'intérieur de la machine. Ensuite, les grains de maïs entreront dans le système de broyage.

- Ensuite, il entre dans le système de classement pour obtenir de la farine de maïs, du gros gruau de maïs et du petit gruau de maïs grâce à une séparation automatique.

- Enfin, la poussière est nettoyée par le système de dépoussiérage Air Net. Nous pourrons alors obtenir des produits propres.

Comment choisir la bonne machine à semoule de maïs ?

Selon la capacité

- Petites exploitations familiales ou agriculteurs : production quotidienne faible ; les modèles T1 ou C2 suffisent.

- Transformation à moyenne échelle : production quotidienne 300–400 kg/h ; les modèles T3 ou PH sont efficaces avec des produits plus propres.

- Transformation à grande échelle / petite ligne de production : production quotidienne élevée et automatisation requises ; choisissez PD2. Il peut être équipé d'un nettoyeur et d'élévateurs pour former une ligne de traitement complète.

Selon le budget

- Petit budget : modèles C2 ou PH ; abordables et fonctionnels.

- Budget moyen : modèles T1 ou T3 ; équilibre entre efficacité et qualité du produit.

- Investissement élevé/ligne de production : PD2 ; peut former une petite ligne de production de semoule de maïs avec la plus grande capacité et efficacité.

Selon les fonctionnalités supplémentaires

- Élimination de la poussière ou séparateur nécessaire ? T3 possède un séparateur cyclone ; PD2 peut être équipé d'un nettoyeur pour des produits plus propres.

- Connexion à un convoyeur ou silo à grains nécessaire ? PD2 peut fonctionner avec des vis sans fin, des élévateurs et des nettoyeurs pour former une ligne de production complète.

Applications du gruau de maïs

Le gruau de maïs est un ingrédient polyvalent avec de nombreuses applications dans diverses industries.

Dans l'industrie agroalimentaire, le gruau de maïs est couramment utilisé pour produire une large gamme de produits tels que des céréales pour petit-déjeuner, des collations, de la semoule de maïs, des tortillas et des produits de boulangerie.

De plus, le gruau de maïs constitue un élément crucial dans l'industrie brassicole, où il est utilisé comme complément à la production de bière pour améliorer la saveur et la consistance.

Au-delà de la consommation humaine, le gruau de maïs est également utilisé dans l'industrie de l'alimentation animale, fournissant une source précieuse de glucides et d'énergie dans les formulations d'aliments pour le bétail.

Choisir la bonne fraiseuse à gruau de maïs

Lors du choix de la machine de fabrication de gruau de maïs, vous devez prendre en compte plusieurs facteurs. Tout d’abord, il est important d’évaluer les besoins de production, notamment le volume de production attendu, la capacité des machines et les spécifications spécifiques du produit.

Deuxièmement, le budget est aussi un facteur clé. Vous devez considérer à la fois le coût d'achat et les coûts d'exploitation et d'entretien à long terme.

La marque est également un facteur important. Choisir une marque réputée avec des notes élevées sur le marché peut augmenter la fiabilité et la durabilité de la machine.

Enfin, la qualité du service après-vente ne doit pas être négligée.

Taizy Machinery est un fabricant professionnel de machines à maïs en Chine. Jusqu'à présent, notre machine de fabrication de gruau de maïs a été exportée vers les États-Unis, le Brésil, l'Argentine, l'Inde, le Mexique, les Philippines et de nombreux autres pays et régions.

Si vous recherchez une fraiseuse à gruau de maïs de haute qualité, n'hésitez pas à nous contacter.

Le client des Philippines a commandé une fraiseuse de gruau de maïs T1

En juin 2022, le client philippin M. Nathan a commandé une machine à gruau de maïs de type T1. Selon le client, il possède une ferme et souhaite acheter une fraiseuse de gruau de maïs pour l'aider à produire des produits agricoles et secondaires de maïs.

Grâce à la communication avec nos ventes, il a décidé d'acheter une machine de notre entreprise. La machine crée désormais de la valeur dans l’exploitation du client.