3-4 тонны/ч Оболочковый аппарат для кукурузы | Высококачественный зерноуборочный комбайн

| Модель | SL-B2 |

| Власть | Двигатель мощностью 2,2 кВт, бензиновый двигатель и дизельный двигатель |

| Емкость | 3-4т/ч |

| Масса | 71kg |

| Размер | 1080*6500*1300 мм |

Теперь вы можете уточнить технические подробности у наших менеджеров проектов.

A maize sheller is an agricultural machine designed to separate kernels from the cob. It achieves a kernel integrity rate of over 98% and a damage rate of less than 3%, making it widely used on large farms.

This corn thresher has a capacity of 3–4 tons/h It is compact, easy to move, and supports multiple power options, including electric motor, gasoline engine, and diesel engine. It fits different working conditions and is ideal for household farmers and farms.

Combined with a corn harvester, large-scale mechanized production can be realized. Due to its excellent performance and high efficiency, this machine has been liked and purchased by customers in many countries. In this article, we will introduce you to a popular maize sheller.

Applications of SL-B2 maize sheller

Industry uses

- Домашние фермеры: Три варианта питания — электродвигатель, бензиновый двигатель или дизельный двигатель — для различных условий в сельской местности

- Пункты сбора зерна: Прямо очищает початки, доставленные фермерами, уменьшая объем транспортировки

- Малые зерноперерабатывающие заводы: Работает с сушилками, мукомолами и машинами для изготовления круп, образуя простую линию переработки

- Сельское предпринимательство: Лица могут предоставлять платные услуги по уборке зерна для ближайших фермеров с помощью зерноуборочного комбайна SL-B2

Applicable crops

By changing the sieve, the machine can also be used for threshing wheat, soybeans, sorghum, and other crops.

- Пшеница

- Горох

- Соевые бобы

- Рис

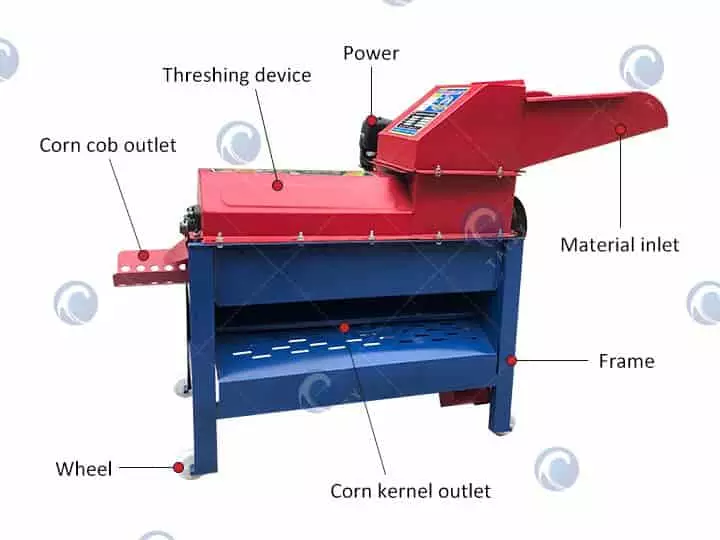

The structure of a corn thresher

The threshing device

The core part of the machine that separates kernels from the cob.

Power unit

Options include electric motor, gasoline engine, or diesel engine, providing power for operation.

Выход для початков кукурузы

The channel where cobs are discharged after threshing.

Material inlet

The entry point for feeding corn cobs into the machine.

Frame

The main supporting structure that ensures stable operation.

Corn kernel outlet

The outlet where kernels are discharged after threshing.

Как работает кукурузоуборочная машина?

Firstly, we need to put the corn cob into the feed port. Then the corn will automatically fall into the threshing chamber.

Then the drum inside the machine will rotate under the action of the motor. The corn will rub and rotate between the rollers. Then the separation of the corn cob and the corn kernel was realized.

Finally, the corn cob will be discharged from the tail of the corn thresher. Corn kernels will fall out of the screen. This is the working process of the commercial corn sheller machine.

Характеристики молотилки для кукурузы

| Модель | SL-B2 |

| Власть | Двигатель мощностью 2,2 кВт, бензиновый двигатель и дизельный двигатель |

| Емкость | 3-4т/ч |

| Масса | 71kg |

| Размер | 1080*6500*1300 мм |

Advantages of the corn thresher

High efficiency

- Capacity: 3–4 tons per hour, 20–30 times more efficient than manual threshing.

Wide applicability

- Can process fresh and dry corn; some models can also thresh wheat, sorghum, and other crops.

Easy operation

- Weight: 71 kg; Dimensions: 1080×650×1300 mm. Compact structure and easy to move.

Multiple power options

Supports electric motor, gasoline engine, and diesel engine, making it easy for farmers to operate.

Time and labor saving

- 3–4 tons per hour can replace the work of about 10–15 people, reducing labor pressure during harvest.

Low Kernel Damage

- Optimized threshing drum design keeps kernel damage below 3%.

Strong cleaning ability

- Equipped with a fan, kernels are clean without extra sieving. Corn cobs remain intact for feed or other uses.

Сколько стоит кукурузоуборочная машина?

The price of a corn thresher is influenced by multiple factors, not just one. The main factors include:

- Capacity: The higher the hourly threshing output, the larger the machine, and the higher the cost.

- Power Type: Different power options—electric motor, gasoline engine, or diesel engine—affect cost; diesel models are usually more expensive than electric ones.

- Multi-functionality: Machines that can handle multiple crops or require customized sieves cost slightly more due to higher customization needs.

- Customization & Additional Services: Custom voltage, size, color, or extra accessories will increase the equipment cost.

If you want to know the latest price of the machine, feel free to contact us. Our sales team will get in touch promptly and provide you with a detailed quotation.

Где купить кукурузную шелуху?

Завод кукурузных машин Taizy является профессиональным производителем кукурузного оборудования. Мы продаем различные виды кукурузной техники, такие как машина для производства кукурузной крупы, мельница для кукурузы и сеялка для кукурузы. Кроме того, мы также предоставляем клиентам качественное предпродажное и послепродажное обслуживание. Многие клиенты стали нашими постоянными покупателями. Поэтому, если вы ищете обоец для кукурузы, пожалуйста, свяжитесь с нами.

Часто задаваемые вопросы

Почему молотьба получается нечистой?

Это может быть вызвано недостаточной скоростью барабана или изношенными зубьями. Проверьте мощность двигателя или замените зубчатую пластину.

Почему высокий уровень повреждения ядра?

Обычно это вызвано слишком высокой скоростью барабана или чрезмерно сухими початками кукурузы. Отрегулируйте скорость или слегка увлажните початки.

Почему машина заедает?

Возможно, потому что слишком много початков подаётся одновременно или мусор блокирует машину. Очистите молотильную камеру и контролируйте количество подачи.

Можете ли вы гарантировать качество?

Конечно. Мы являемся производственным предприятием. Что ещё важнее, мы придаём большое значение нашей репутации.

Лучшее качество всегда — наш принцип. Вы можете быть полностью уверены в нашей продукции.

Ваша компания принимает индивидуальные заказы?

У нас отличная команда дизайнеров, и мы можем принимать OEM-заказы.

Как насчёт вашего сервиса?

Круглосуточный онлайн-сервис для решения любых проблем. Ваше удовлетворение — наше стремление. Искренне надеемся на сотрудничество.

Какие способы доставки доступны?

For urgent order and light weight, you can choose express: FEDEX, TNT, DHL or EMS; for heavy weight, you can choose by air or by sea to save cost.

How can I get to your factory?

We are in No.1394 East Hanghai Road, Economic-technological Development Area, Zhengzhou, China. And we can provide free and considerate receptions for you.