मक्का, चावल और गेहूं पीसने के लिए कॉर्न हैमर मिल मशीन

| मॉडल | 9FQ श्रृंखला |

| क्षमता(किलोग्राम/घंटा) | 100-3000 |

| शक्ति (किलोवाट) | 2.2-55 |

| छानने का व्यास (मिमी) | 0.5-5 |

| हथौड़े (पीस) | 16/24/32/40/64 |

| वजन (किलोग्राम) | 50-1200 |

| आकार (मिमी) | चार्ट अनुसार |

| वारंटी | 12 महीने |

आप अब हमारे परियोजना प्रबंधकों से तकनीकी विवरण पूछ सकते हैं

The corn hammer mill machine is a multifunctional grinding machine. It can efficiently crush grains such as corn, wheat, and soybeans, as well as process materials like wheat straw, corn stalks, and peanut shells into fine powder or pellets. It is an ideal choice for feed production and agricultural waste recycling.

विभिन्न मॉडलों के अनुसार, Taizy के कॉर्न हैमर मिल मशीनों की क्षमता 100–3000 kg/h, की रेंज में है, जो अधिकांश व्यवसायों की जरूरतों को पूरा करती है।

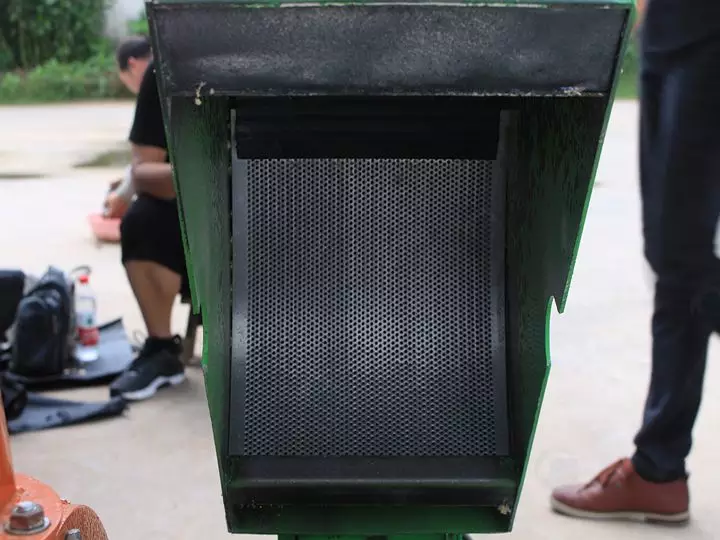

This hammer mill machine has a wide range of applications and can produce materials with different particle sizes. The fineness of the powder mainly depends on the size of the screen holes. We can customize screens with different apertures based on your raw materials to ensure the final product meets your production needs. Common screen sizes include 2mm, 3mm, 4mm, 5mm, 8mm, and 10mm.

Our corn hammer mill can be powered by a diesel engine, gasoline engine, or electric motor, making it suitable for various working conditions. The engine can reach up to 75 HP, providing strong power and high efficiency.

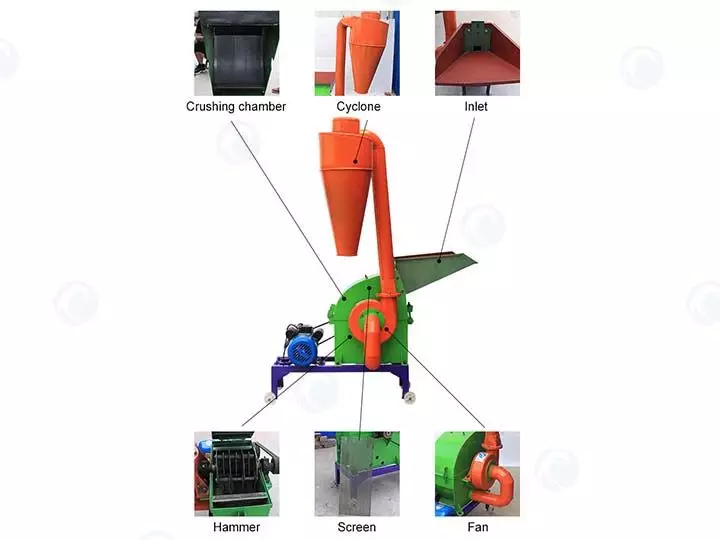

मक्का हैमर मिल डिजाइन

कॉर्न आटा हैमर मिल की संरचना में एक क्रशिंग चैंबर, एक फीडिंग चैंबर, एक साइक्लोन पृथक्करण चैंबर, एक रोटर और एक बेस शामिल हैं।

Feeding Chamber

- कार्य: मिश्रित रूप से कच्चे माल जैसे मकई, अनाज, और भूसे को क्रशिंग चैम्बर में फीड करता है।

- विशेषताएँ: धूल रिसाव से बचाने के लिए बैकफ्लो रोकथाम उपकरण से लैस; स्वचालित फीडर के साथ जोड़ा जा सकता है ताकि निरंतर फीडिंग हो सके।

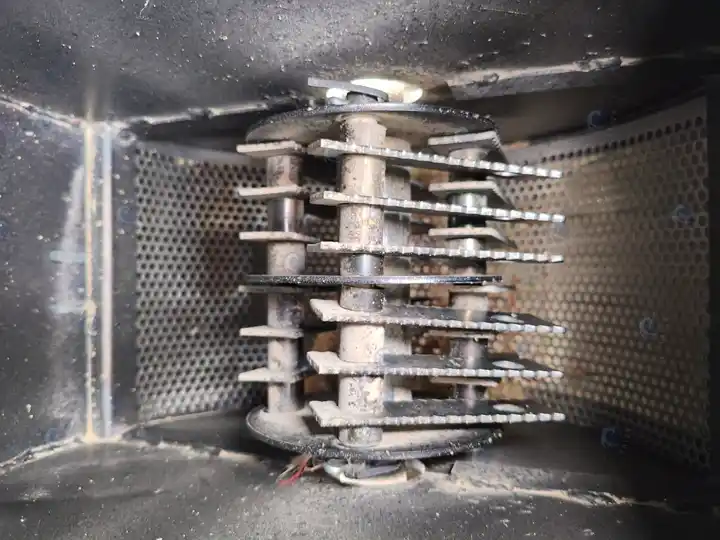

Crushing Chamber

- कार्य: मशीन का मुख्य कार्य भाग, जहां कच्चे माल को उच्च गति हथौड़ा प्रभाव, काटने, और घर्षण से पाउडर या गोली में क्रश किया जाता है।

- घटक: हथौड़े, रोटर, स्क्रीन, और लाइनर शामिल हैं।

- विशेषताएँ: पाउडर की महीनता को नियंत्रित करने के लिए प्रतिस्थापन योग्य स्क्रीन छेद।

Rotor

- कार्य: मशीन हामर्स को उच्च गति पर घुमाने के लिए चलाता है ताकि सामग्री को क्रश किया जा सके।

- विशेषताएँ: अच्छी संतुलित, उच्च गति (आम तौर पर 2800 RPM से अधिक), सीधे क्रशिंग दक्षता और कण समानता को प्रभावित करता है।

Cyclone Separator

- कार्य: क्रश किए गए पाउडर को हवा से अलग करता है ताकि संग्रह सुगम हो और धूल का ओवरफ्लो कम हो।

- विशेषताएँ: सेंट्रीफ्यूगल बल का उपयोग करके पृथक्करण; सरल संरचना के साथ प्रभावी धूल निकास।

मशीन के पैरामीटर क्या हैं?

| मॉडल | क्षमता(किलोग्राम/घंटा) | हैमर(पीसी) | शक्ति(किलोवाट) | Power(HP) | छानने का व्यास(mm) | वजन(किलोग्राम) | आकार (मिमी) |

| 9FQ-320 | 100 | 16 | 2.2 | 5 | 0.5-5 | 50 | 1200*500*1000 |

| 9FQ-360 | 150 | 24 | 5.5 | 8 | 0.5-5 | 120 | 1100*600*1200 |

| 9FQ-420 | 200 | 24 | 11 | 15 | 1.2-3 | 200 | 1200*800*1900 |

| 9FQ-500 | 300 | 24 | 11 | 20 | 1.2-3 | 300 | 1200*800*1300 |

| 9FQ-600 | 500 | 32 | 18.5-22 | 30 | 1.2-3 | 500 | 1500*900*1500 |

| 9FQ-750 | 850 | 32 | 22-30 | 35 | 1.2-3 | 850 | 1500*1000*1600 |

| 9FQ-800 | 1000 | 40 | 37 | 45 | 1.2-3 | 1000 | 2000*1300*1600 |

| 9FQ-1000 | 1200 | 64 | 45- | 75 | 1.2-3 | 1200 | 1500*1300*1800 |

The above are the parameters of 8 popular corn hammer mill models. The small corn hammer mill has a capacity of 100 kg/h, while the large corn flour machine can reach 1200 kg/h. If you are interested, please feel free to contact us. We also have the corn grits milling machine and the disk corn mill machine for sale.

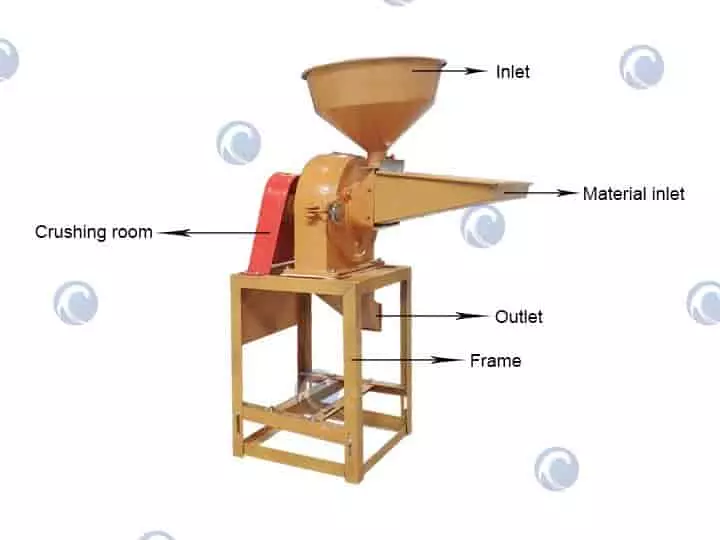

मक्का हैमर मिल मशीन कैसे काम करती है?

मक्का के आटे की चक्की का कार्य करने का तरीका बहुत सरल है। सबसे पहले, ऑपरेटर पावर सप्लाई चालू करता है और सामग्री को फीडिंग पोर्ट पर भेजता है। फिर सामग्री स्वचालित रूप से पीसने के कक्ष में प्रवेश करती है। क्रशिंग कक्ष में उच्च गति वाला हथौड़ा जल्दी से मक्का को पाउडर या दानों में पीस देता है। अंतिम उत्पाद स्क्रीन के माध्यम से आउटलेट से निकाला जाएगा।

Advantages of the corn grinding hammer mill

- विस्तृत क्षमता सीमा: 100 किग्रा/घंटा से 1200 किग्रा/घंटा तक की क्षमता के साथ, यह छोटे से मध्यम बड़े उत्पादन की आवश्यकताओं को पूरा करता है।

- शक्तिशाली और प्रभावी: डीजल इंजन, गैसोलीन इंजन, या इलेक्ट्रिक मोटर से संचालित किया जा सकता है, जिससे प्रभावी क्रशिंग और स्थिर प्रदर्शन सुनिश्चित होता है।

- टिकाऊ सामग्री और संरचना: शरीर उच्च गुणवत्ता वाले स्टील से बना है, जंगरोधक और मजबूत; रोटर, हथौड़े, और लाइनर पहनने वाले मिश्र धातु सामग्री से बने हैं, जिससे सेवा जीवन बढ़ता है।

- समायोज्य कण आकार: प्रतिस्थापन योग्य स्क्रीन के साथ, जिसमें 2–12 मिमी के छेद हैं, विभिन्न उत्पादन आवश्यकताओं को पूरा करने के लिए पाउडर की महीनता का सटीक नियंत्रण।

- व्यापक अनुप्रयोग: मकई, गेहूं, सोयाबीन, भूसा, मूंगफली के छिलके, और अन्य फसलों या कृषि अवशेषों को महीन पाउडर या गोली में क्रश कर सकता है, जो फीड उत्पादन और कृषि अपशिष्ट पुनर्चक्रण के लिए आदर्श है।

- कॉम्पैक्ट और व्यावहारिक डिज़ाइन: मशीन के आकार 1200×500×100 मिमी से 2000×1300×1600 मिमी तक हैं, आसान स्थापना और रखरखाव के लिए कॉम्पैक्ट संरचना।

- उच्च प्रदर्शन रोटर: अच्छी संतुलित रोटर, जिसकी गति 2800 RPM से अधिक है, सुनिश्चित करता है कि कण का आकार समान हो और क्रशिंग प्रभावी हो।

- प्रभावी धूल नियंत्रण: धूल रिसाव को कम करने के लिए प्रभावी रूप से धूल को अलग करने के लिए साइक्लोन सेपरेटर से लैस।

मक्का हैमर मिल का सही तरीके से उपयोग कैसे करें?

- मशीन शुरू करने से पहले, जांचें कि क्या मशीन के प्रत्येक भाग में स्पष्ट रूप से कोई असामान्यता है और क्या स्क्रू ढीले हैं।

- The machine should idle for several minutes when starting. Listen for abnormal sounds and a loose belt.

- The user shall not put their hand into the machine during feeding.

- A bag shall be connected at the exit to collect the finished products. This can avoid the situation where powdery materials are not easy to collect.

- जब मशीन 500 घंटे तक चलती है, तो बेयरिंग की जांच करें और स्नेहक तेल बदलें।

- After the work of the corn hammer mill machine is completed, the feed inlet shall be closed, and the leftovers shall be cleaned.

How to choose the right corn hammer mill machine?

Choose by capacity

| क्षमता (किग्रा/घंटा) | Suitable Model | Notes |

|---|---|---|

| 100–150 | 9FQ-320 / 9FQ-360 | Small-scale production or household/farm use |

| 200–300 | 9FQ-420 / 9FQ-500 | Small to medium feed mills or small corn processing |

| 500–850 | 9FQ-600 / 9FQ-750 | Medium-sized enterprises, high efficiency |

| 1000–1200 | 9FQ-800 / 9FQ-1000 | Large-scale corn processing or industrial production |

Tip: Choose a model slightly above your actual needs (10–20%) to handle peak production and prevent overloading.

Consider hammer quantity & power

- More hammers → higher crushing efficiency, finer and more uniform particles.

- Proper power → ensures stable operation; too low causes motor overload, too high wastes energy.

| पावर (kW) | Recommended Capacity | विशेषताएँ |

|---|---|---|

| 2.2–5 | 100–150 kg/h | Household or small feed mills |

| 11–22 | 200–850 kg/h | Medium-scale production, suitable for continuous operation |

| 37–45 | 1000–1200 kg/h | Industrial high-capacity, heavy-duty operation |

Tip: Match hammer number and power with the required capacity.

Consider the screen diameter for particle size

- Small screens (0.5–1.5 mm) → finer powder, suitable for flour, feed, or industrial use.

- Larger screens (2–5 mm) → coarse particles, suitable for feed or corn grits.

Choose according to downstream usage: feed, corn flour, or corn powder.

Consider machine size and workshop space

- Small models (9FQ-320 / 360) → occupy less space, suitable for limited workshops.

- Large models (9FQ-800 / 1000) → occupy more space, may require conveyors or hoppers.

Selection process summary

- Determine hourly/day capacity → shortlist suitable models.

- Consider material characteristics (hardness, moisture, usage) → choose power and screen size.

- Check workshop space → ensure machine fits.

- Evaluate budget → small models are cheaper, large models are more productive but occupy more space.

- Plan for future expansion → select a machine slightly above current capacity.

Example

- Small feed mill, ~200 kg/h → choose 9FQ-420, 11 kW, 24 hammers, screen 1.2–3 mm, cost-effective and easy to maintain.

- Industrial corn processing, >1000 kg/h → choose 9FQ-800 or 9FQ-1000, high power, more hammers, stable high-capacity production.

Successful case

Corn hammer mill machine sold to Morocco distributor

- Customer: A distributor from Morocco

- Machine Model: 9FQ-320 Corn Hammer Mill

- Quantity: 74 sets

- Capacity: 100–200 kg/h

- Size: 660×350×850 mm

- पावर: 2.2 किलowatt

- Voltage: 220V

- Weight: 70 kg

- Features: Equipped with a copper core motor, 2 m belt cover, and European standard plug

विवरण

- The Moroccan distributor purchased 74 sets of small hammer mills to expand their local feed production network.

- The 9FQ-320 model was chosen for its compact structure, stable performance, and easy operation, making it ideal for small-scale farms and feed workshops.

- Each machine is equipped with a copper core motor and a safety belt cover, ensuring efficient and safe operation.

- Our team provided professional installation and operation guidance to help the customer quickly start production.

If you are interested in our corn hammer mill, please leave your contact information and requirements in the pop-up form on the right. We will get in touch with you within 24 hours to provide more details and a quotation.